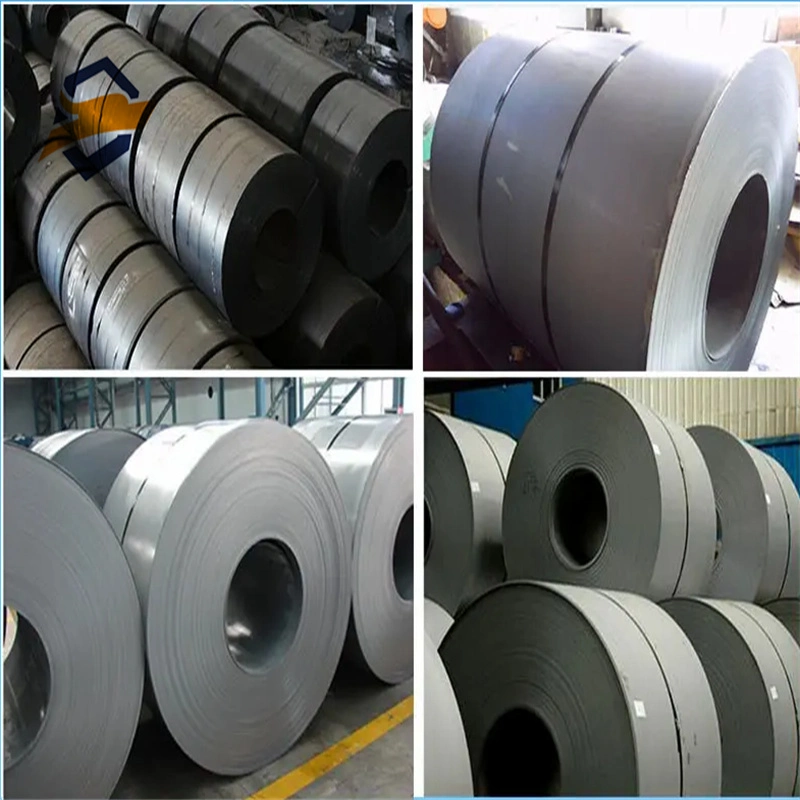

Commercial Grade 5mm-20mm MS Carbon Steel Iron Metal Coil SPHC SS400 Hot Rolled Steel Coils Q235 Q345 Mild Steel HRC HR Steel Strip/Sheet/Coils

Product Description

Hot Rolled Steel Coil General Introduction:

Carbon steel is an iron-carbon alloy with a carbon content of 0.0218%~2.11%, also known as carbon steel. It also contains small amounts of silicon, manganese, sulfur and phosphorus. In general, the higher the carbon content, the greater the hardness, the higher the strength, but the lower the plasticity.

1.According to the use of carbon steel can be divided into carbon structural steel carbon tool steel and free cutting structural steel three categories, carbon structural steel is divided into engineering construction steel and machine manufacturing structural steel.

2. According to the deoxidation method, it can be divided into rimmed steel (F) killed steel (Z) semi-killed steel (B) and special killed steel (TZ).

3. According to the quality of steel, carbon steel can be divided into ordinary carbon steel (containing phosphorus and sulfur higher) high quality carbon steel (containing phosphorus and sulfur lower) and high quality steel (containing phosphorus and sulfur lower) and super quality steel.

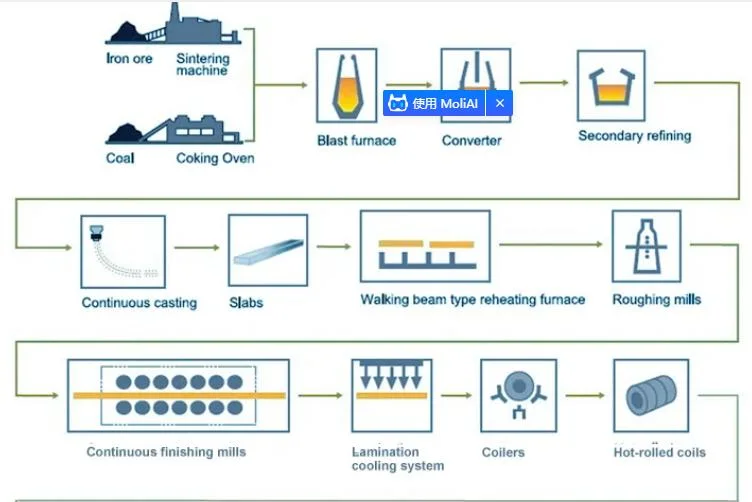

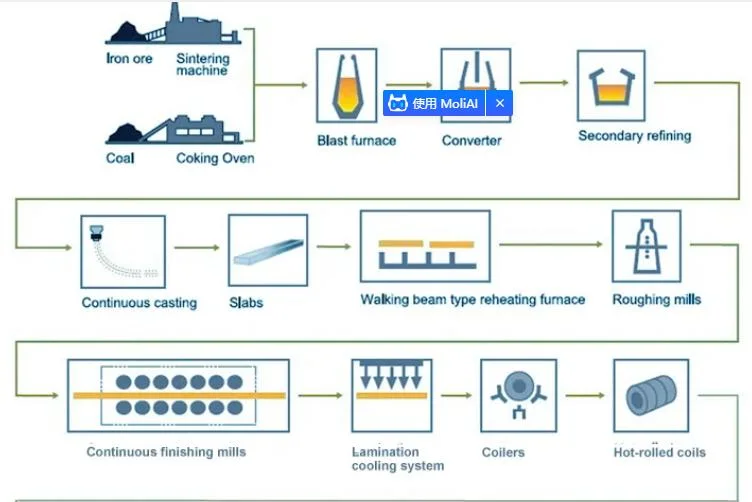

The hot-rolled steel coil is made of continuous casting slab or blooming slab as raw material, heated by a walking furnace, descaled by high-pressure water, and then enters the rough rolling mill. Controlled rolling, after the final rolling, it undergoes laminar cooling (computer controlled cooling rate) and coiler coils to become a straight hair coil.

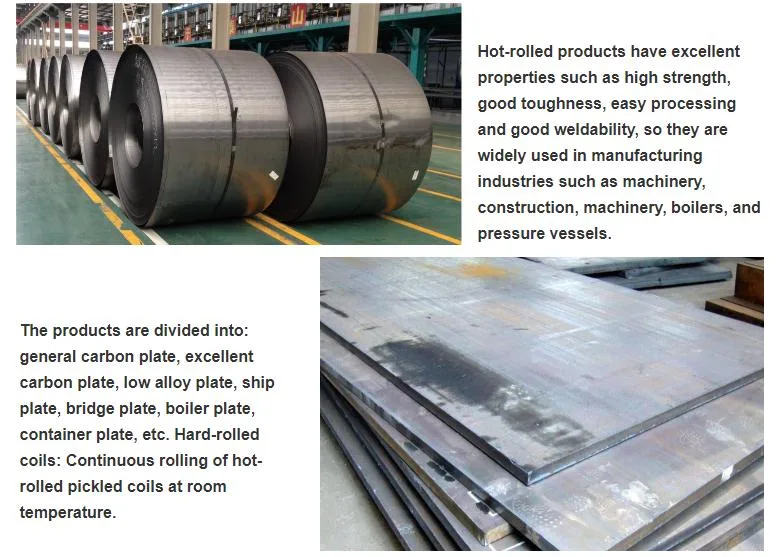

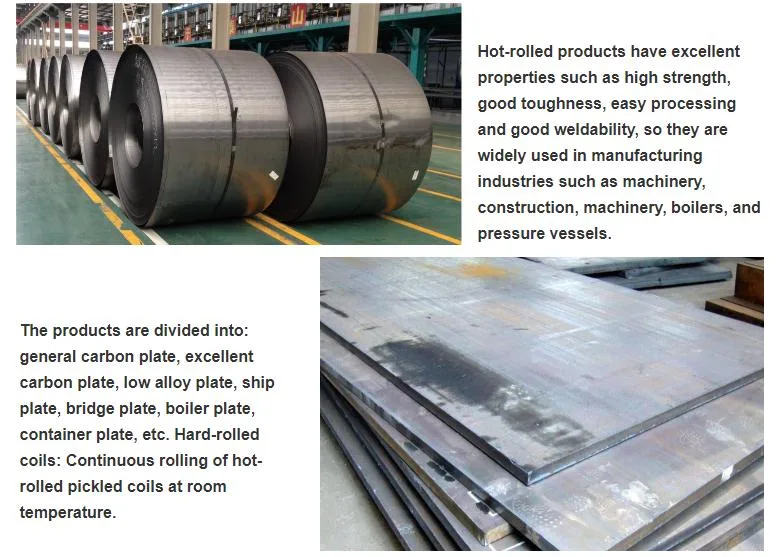

Hot-rolled steel coil has excellent properties such as high strength, good toughness, easy processing and good weldability, so it is widely used in manufacturing industries such as machinery, construction, machinery, boilers, and pressure vessels.

Product Parameters

Carbon Steel Coil Specification:

| Product |

Carbon Steel coil/roll/Mild Steel Coil/MS Iron Coil/HRC |

| material |

A36, SS400, Q345B, Q235B, Grade50, Q460,St37-2,SA283Gr,S235JR,S235J0,S235J2 |

| Standard |

ASTM EN DIN GB ISO JIS BA ANSI |

| Technology |

hot rolled cold rolled (as custom's request) |

| Thickness |

1.0-50mm (Or as custom's request) |

| Width |

785-2000MM |

| Surface Treatment |

Black painted,PE coated,Galvanized,color coated,

anti rust varnished,anti rust oiled,checkered,etc |

| Processing Method |

Bending, Welding, Decoiling, Cutting, Punching, Polishing or as customer's request |

| Shipment time |

within 7-15 workdays |

| Applications |

It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture,

ship components.

It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs,

and screen. |

|

|

|

|

General Carbon Structual Steel

|

Q195,Q215A,Q215B,Q235A,Q235B,Q235C,Q235D

|

|

|

SS330,SS440,SS490

|

|

|

DC01,DD11,DD12,DD13,DX51,S185,S235,S275,S355,E295

|

|

|

SAE1006,SAE1008,SAE1010,SAE1012,SAE1017,SAE1022

|

|

Carbon Constructional Quality Sreel

|

08AI,10,20,30,35,45

|

|

|

C35,C40,C45,C50,C60

|

|

|

SAE1006,SAE1008,SAE1010,SAE1012,SAE1017,SAE1022

|

|

|

|

08,15,Q215,Q275A,Q390A

|

|

|

SN400A,SN400B,SN490B

|

|

|

|

Q235,Q345,Q390,Q420,Q460

|

|

|

SM400,SM490,SM520,SM570

|

|

|

|

Q235,Q245

|

|

|

SPHT1,SPHT2,SPHT3,SPHT4

|

|

|

|

|

|

|

Impact Test

(Longitudinal)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

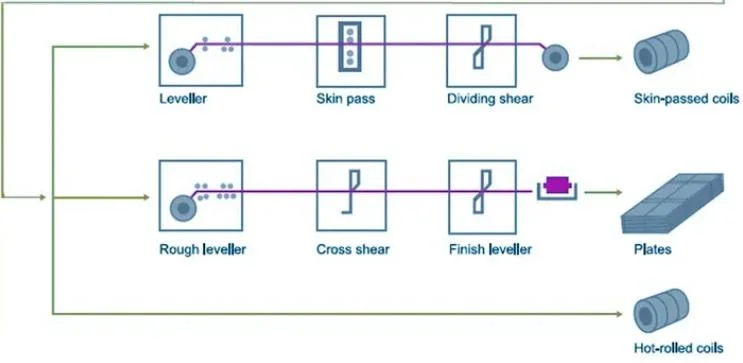

Processing

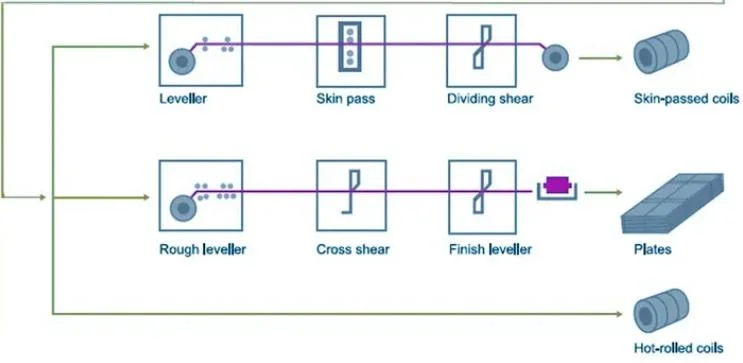

Mild Steel HRC Process:

MS Carbon Steel HRC Description:

MS Carbon Steel HRC Description:

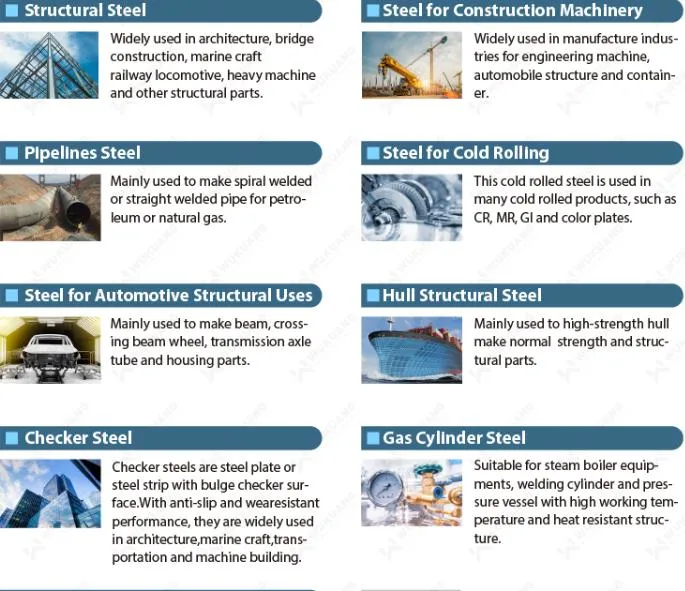

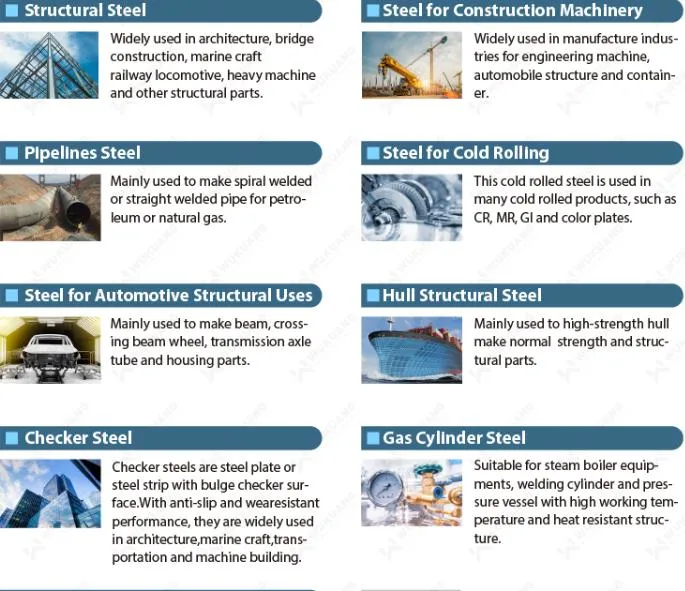

Product Application

Carbon Steel HRC Application:

Hot-rolled products have excellent properties such as high strength, good toughness, easy processing and good weldability, so they are widely used in manufacturing industries such as steel, construction, machinery, boilers, and pressure vessels etc.

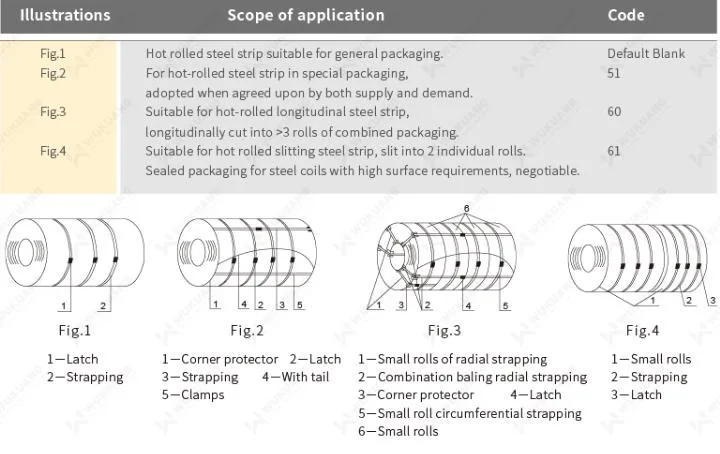

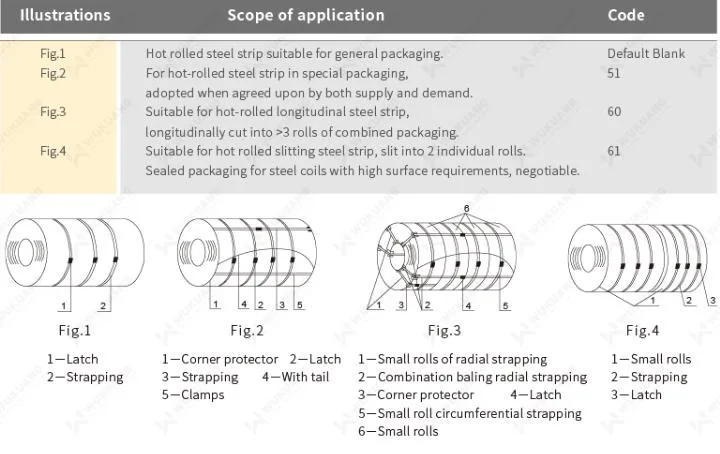

Packaging & Shipping

Carbon Steel HRC Package&Delivery:

Our Service

FAQ

Q:Can I get samples before order ?

A:Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

Q:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q:How can I get a quotation from you ?

A:You can leave us message, and we will reply every message in time. Or we may talk on line.

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed. we accept the third party inspection absolutely.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!