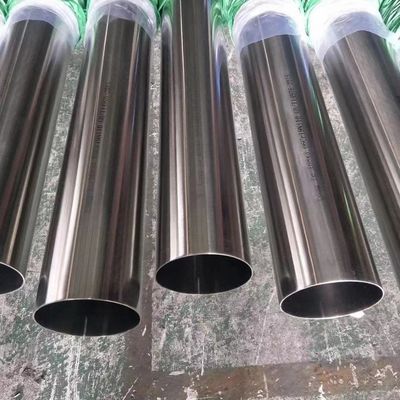

High Grade Nickel Alloy Steel with High Hardness Alloy B2 and Hydrogen Annealing Treatment

Product Description:

Nickel Alloy Steel is a type of alloy steel made from a combination of Nickel, Molybdenum, and Chromium. It is an extremely strong, durable and corrosion-resistant metal that can withstand extreme temperatures and pressures in a variety of industrial applications. Nickel Alloy Steel is widely used in industries including aerospace, automotive, medical, military, and nuclear engineering. It is available in a variety of shapes and sizes, and is often custom-designed for specific products and applications. Standard grades of Nickel Alloy Steel are available in JIS, ASTM, DIN, EN, JIS, AISI, and GB specifications.

Nickel Alloy Steel offers numerous benefits, including superior strength, high thermal and electrical conductivity, and excellent corrosion and oxidation resistance. The surface finish of Nickel Alloy Steel can be brushed, mirrored, or 2B. It is available in different tempers, such as O-H112, and can be subjected to hydrogen annealing treatment to further improve its properties. Its high strength and low weight make it an ideal choice for a variety of industries, including oil and gas, chemical processing, and power generation. Nickel-Molybdenum-Chromium, Nickel-Moly-Chrome, and Nickel-Chrome-Moly alloys are all common varieties of Nickel Alloy Steel.

Nickel Alloy Steel is a versatile and reliable material that can be used in a wide range of applications. Its superior mechanical properties and excellent wear resistance make it a popular choice for many industries. It is also available in a variety of shapes and sizes with different radii, such as LR. Whether you are looking for a standard grade or a custom-designed product, Nickel Alloy Steel is the ideal choice for a variety of applications.

Features:

- Product Name: Nickel Alloy Steel

- Composition: Nickel-Moly-Chrome Alloy Steel, Nickel-Molybdenum-Chromium Alloy Steel, Ni-Mo-Cr Alloy Steel

- Surface: Bright, Oxidized Or Pickling

- Thickness: 0.1mm -60mm

- Inspection: 100%

- Wire Gauge: 0.128-12mm

- Surface Finish: Brushed ,Mirror , 2B

Technical Parameters:

| Attribute |

Value |

| Wire Gauge |

0.128-12mm |

| Heat Treatment |

Solid Solution And Aging Treatment |

| Processing Service |

Welding, Cutting |

| Temper |

O-H112 |

| Inspection |

100% |

| Treatment |

Hydrogen Annealing |

| Grade |

Alloy B2 |

| Standard |

JIS, ASTM, DIN, EN, JIS, AISI,GB,etc |

| Model Number |

600 |

| Thickness |

0.1mm -60mm |

| Material |

Nickel-Chrome-Molybdenum-Alloy Steel, Nickel-Chrome-Moly Alloy Steel, Nickel-Chromium-Molybdenum-Iron Alloy Steel |

Applications:

Nickel Alloy Steel is a special type of steel alloy that contains nickel, molybdenum, chromium, and other metals. It is widely used in various industries, including aerospace, automotive, and manufacturing. This type of steel has superior strength and durability compared to other types of steel, making it a popular choice for a wide variety of applications. It is also known for its corrosion resistance and high temperature capabilities. Nickel Alloy Steel has excellent weldability and is easy to machine and fabricate.

Nickel Alloy Steel is often used in the production of industrial parts and components, such as valves, pumps, and turbines. Its superior strength and durability make it a popular choice for construction projects as well. It is also used in the automotive industry for a variety of components, such as engine parts and exhaust systems. In addition, it is often used in the production of medical devices and dental implants. Nickel Alloy Steel is also used in the production of kitchen and bathroom fixtures, as well as other household items.

Nickel Alloy Steel is available in a variety of sizes and thicknesses, ranging from 0.1mm to 60mm. It is available in a range of finishes, including brushed, mirror, and 2B. It is also treated with hydrogen annealing to ensure a uniform surface finish. Nickel Alloy Steel is available in a variety of standards, including JIS, ASTM, DIN, EN, JIS, AISI, GB, and others. It is available in a range of surface finishes, including bright, oxidized, or pickled.

Nickel Alloy Steel is an excellent choice for a variety of applications, due to its superior strength and durability. It is available in a variety of sizes and thicknesses, and is treated with hydrogen annealing to ensure a uniform surface finish. It is available in a range of standards, and is available in a range of surface finishes. Nickel Alloy Steel is a popular choice for a wide variety of applications, due to its superior strength and durability.

Customization:

Customized Service for Nickel Alloy Steel

Product Attributes:

- Brand Name: Nickel Alloy Steel

- Model Number: Nickel Alloy Steel

- Place of Origin: Jiangsu

- Heat Treatment: Solid Solution And Aging Treatment

- Temper: O-H112

- Wire Gauge: 0.128-12mm

- Surface Finish: Brushed, Mirror, 2B

- Model Number: 600

Our Nickel Alloy Steel is made of Nickel-Chrome-Molybdenum-Alloy Steel, Nickel-Molybdenum-Chromium Alloy Steel, Ni-Cr-Fe-Mo Alloy Steel. It is well known for its superior heat treatment and high temperature performance.

Support and Services:

Nickel Alloy Steel Technical Support and Service

Our team of experienced technicians is available 24/7 to provide technical support and service for Nickel Alloy Steel. We can provide technical advice, troubleshooting, maintenance, and repairs. We also offer custom services, such as welding, machining, and fabrication. Our knowledgeable staff is here to help you with all your Nickel Alloy Steel needs.

Packing and Shipping:

Packaging and Shipping

Nickel Alloy Steel is packaged securely to guarantee safe arrival to our customers. We offer a variety of shipping options, including ground, air, or expedited delivery, to ensure the product reaches its destination quickly and safely.

FAQ:

- Q1: What is Nickel Alloy Steel?

- A1: Nickel Alloy Steel is a kind of alloy steel made of nickel and other chemical elements.

- Q2: What is the Brand Name of Nickel Alloy Steel?

- A2: The Brand Name of Nickel Alloy Steel is Nickel Alloy Steel.

- Q3: What is the Model Number of Nickel Alloy Steel?

- A3: The Model Number of Nickel Alloy Steel is Nickel Alloy Steel.

- Q4: Where does the Nickel Alloy Steel come from?

- A4: The Nickel Alloy Steel comes from Jiangsu, China.

- Q5: What are the advantages of Nickel Alloy Steel?

- A5: Nickel Alloy Steel has good corrosion resistance, good wear resistance, good thermal and electrical conductivity, and high strength.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!