Product Description:

Stainless Steel Sheet

The Stainless Steel Sheet is a type of steel sheet made from high quality stainless steel. It is widely used in various industries such as architecture, elevator, kitchenware, decoration, and furniture. With its excellent corrosion resistance, durability, and aesthetic appeal, this product has become a popular choice for both commercial and residential applications.

Product Overview

The Stainless Steel Sheet is available in three different hardness levels: Soft, Half Hard, and Hard. This allows customers to choose the most suitable option for their specific needs. It is also offered in various sizes and thicknesses, making it suitable for a wide range of applications.

Price Terms

The Stainless Steel Sheet is available in different price terms such as CIF, CFR, FOB, and Ex-Work. This allows customers to choose the most convenient and cost-effective option for their location and requirements.

Hardness

The hardness of the Stainless Steel Sheet can be customized according to customer requirements. It is available in Soft, Half Hard, and Hard variants, providing different levels of strength and flexibility to meet the diverse needs of customers.

Standard

The Stainless Steel Sheet is manufactured in compliance with the ASTM A240 standard, ensuring high quality and consistency in its production. This standard is widely recognized and accepted in the industry, providing customers with peace of mind and assurance of the product's quality.

Package

The Stainless Steel Sheet is packaged in a standard export package, ensuring safe and secure transportation. This package is designed to protect the product from any damage during shipping, maintaining its quality and appearance.

Application

The Stainless Steel Sheet is suitable for various applications such as architecture, elevator, kitchenware, decoration, and furniture. Its versatility and durability make it an ideal choice for both commercial and residential projects. It is also commonly used in industrial settings for its excellent corrosion resistance.

Key Features

- Embossed Stainless Steel Sheet - The surface of the Stainless Steel Sheet is embossed with a unique pattern, adding a decorative element to the product.

- Cold Rolled Stainless Steel Sheet - The Stainless Steel Sheet is produced using the cold rolling process, resulting in a smooth and uniform finish.

- Textured Stainless Steel Sheet - The texture of the Stainless Steel Sheet adds a tactile element to the product, making it visually appealing and unique.

Overall, the Stainless Steel Sheet is a high-quality and versatile product that offers excellent durability, corrosion resistance, and aesthetic appeal. Its customization options, various price terms, and standard compliance make it a popular choice among customers for a wide range of applications.

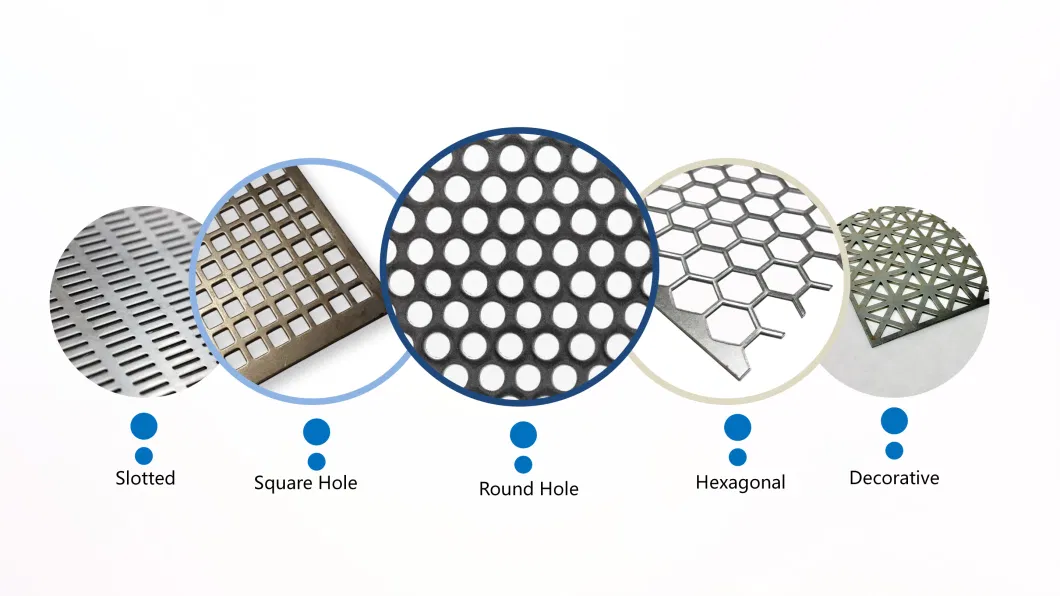

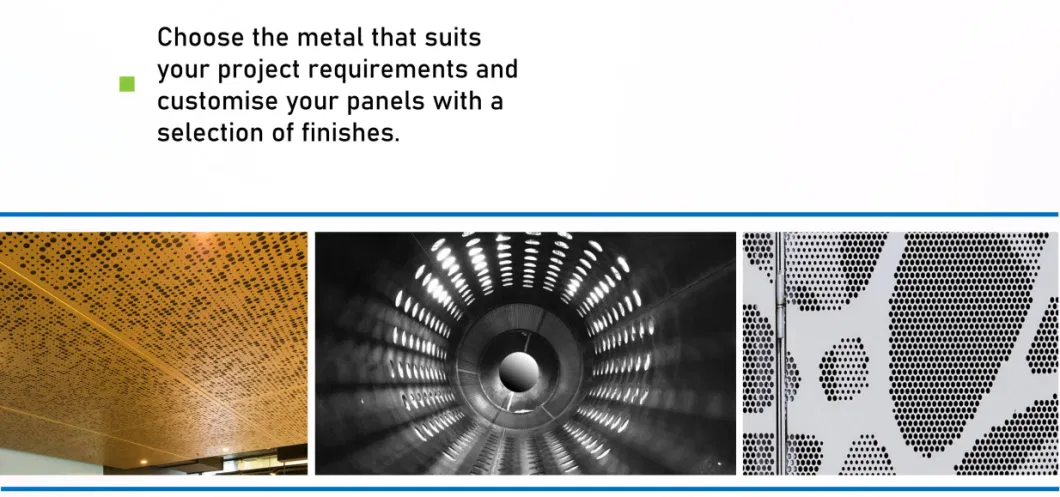

What is a perforated sheet?

A perforated sheet is a metal sheet that's punched or cut to produce a pattern of holes, slots or shapes for practical or aesthetic purposes. It's also known as "perforated metal."

This type of metal sheet includes decorative hole patterns such as circles, squares, triangles, diamonds, hex, slots, bars and so forth. By combining shapes, it is possible to create more complex designs.

| Perforated metal |

| Material |

Carbon Steel Plate, Galvanized steel Plate, Stainless Steel Plate, Aluminum Plate, etc |

| Thickness |

0.5mm-12mm |

| Sheet size |

1000mmx1000mm, 1000mmx2000mm, 1200mmx2400mm, 1220mmx2440mm,etc |

| |

- Without treatment |

| |

For carbon steel material : |

| Surface |

- Galvanized : Electric galvanized, Hot-dipped galvanized |

| treatment |

- Powder coated (colour can be silver, blue,green,yellow,pink,red,black,as you like) |

| |

For aluminum material : |

| |

- Anodized |

| |

- PVDF(surface will be much more smooth, level off and glossy, it also has a much longer life span than common treatment) |

| Hole shape |

Round, Rectangular,Square, Triangle, Diamond, Hexagonal, Cross, Slotted and any other special patterns |

| Categories |

CNC perforating,CNC turret perforating,Laser cutting,Water jet cutting,Coil to coil perforating,Coil to pieces perforating,Etching, etc. |

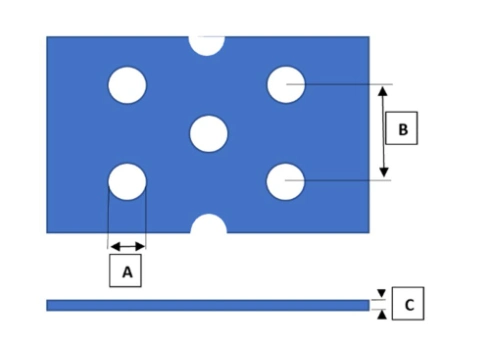

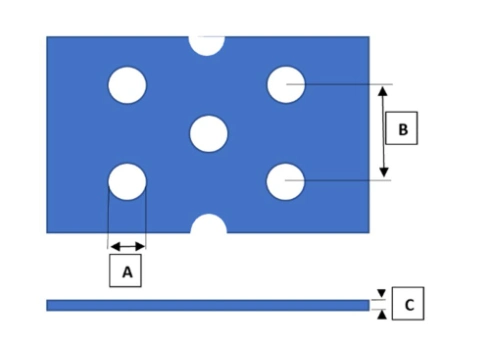

How do you measure it?

Using common perforated sheet terminology, we'd start by looking at the hole pattern ('staggered hole") followed by the hole size (i.e., a circle diameter) [A], the "stagger' (the distance between holes from center to center) [B] and finally the sheet gauge (or thickness) [C]. You typically measure the dimensions in millimetres.

Using common perforated sheet terminology, we'd start by looking at the hole pattern ('staggered hole") followed by the hole size (i.e., a circle diameter) [A], the "stagger' (the distance between holes from center to center) [B] and finally the sheet gauge (or thickness) [C]. You typically measure the dimensions in millimetres.

Example: Staggered Hole 1.000" X 1.250" X 11 Ga. (or 0.125"). This refers to a staggered hole pattern with 1-inch diameter holes spaced 1.25-inches apart on 11-gauge sheet material.

A hole pattern is the arrangement of holes on a sheet in either staggered or straight rows.

In a staggered hole pattern, the direction of the stagger is typically parallel to the short dimension of the sheet. The 60° staggered is the most common pattern. Although other designs are available, 60° staggered is the strongest, most versatile and most economical perforated pattern.

"Gauge" is a British term that refers to sheet thickness. It originated before the advent of the standard metric and standard measurement systems but remains a common term for wire diameter and sheet thickness.

As a rule of thumb, the higher the gauge number, the thinner the metal thickness.

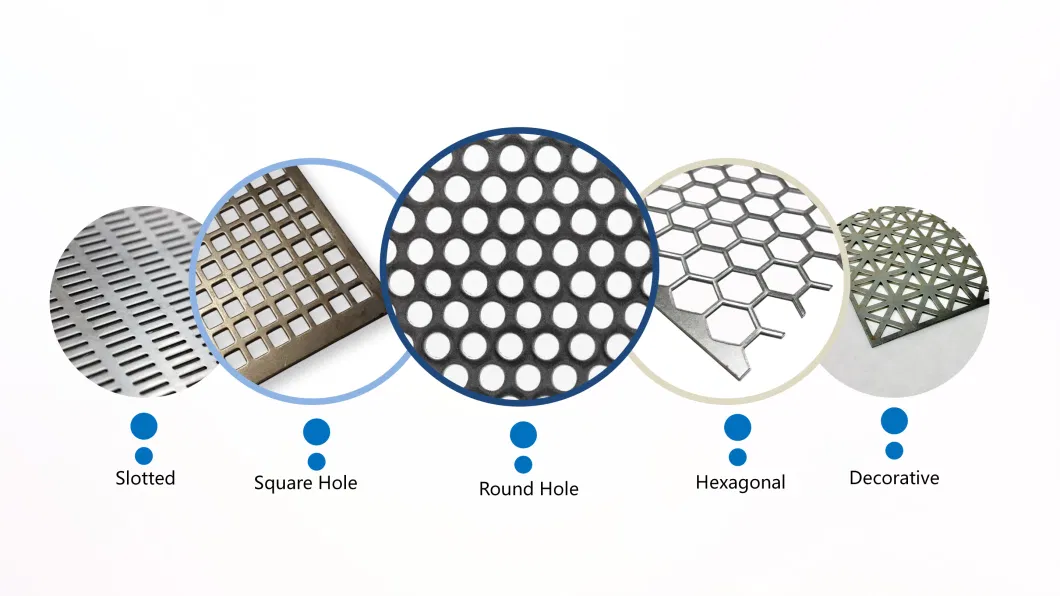

Types of Perforated Metals

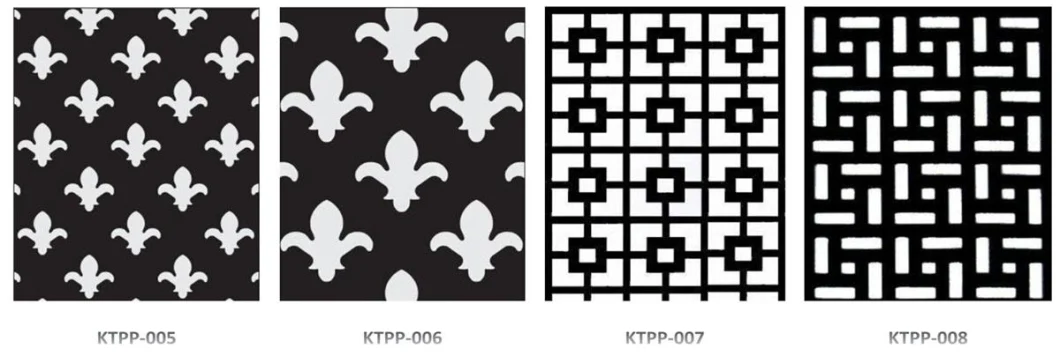

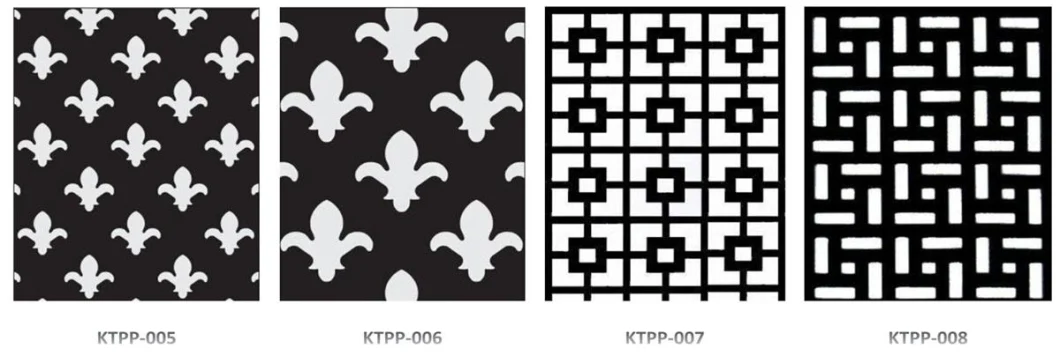

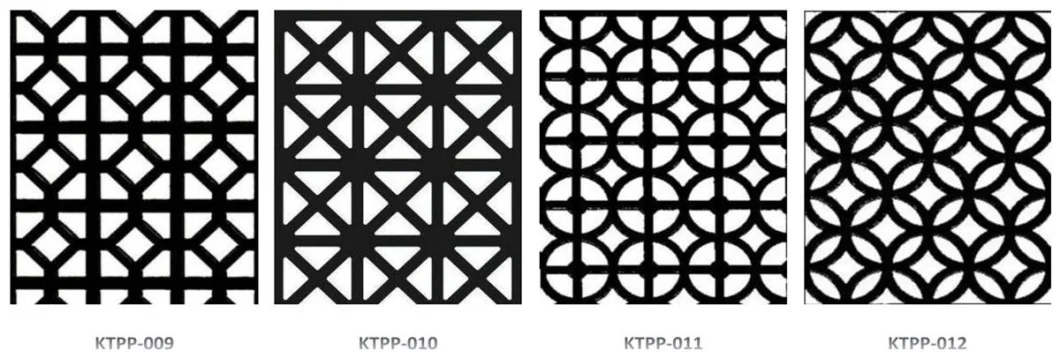

Other Regular Patterns

Other Regular Patterns

The determination of the pattern depends on the intended use of the perforated metal, which comes in standard and custom designs as well as a variety of sizes, shapes, and arrangement of holes. The required strength, application, and how the holes are configured have an effect on the functionality and efficiency of the perforated metal.

The determination of the pattern depends on the intended use of the perforated metal, which comes in standard and custom designs as well as a variety of sizes, shapes, and arrangement of holes. The required strength, application, and how the holes are configured have an effect on the functionality and efficiency of the perforated metal.

Part of the decision process involves an examination of the hole and bar size. Bars are the spaces between the holes. The proper balance of the holes and bars is an essential factor that determines the strength of the perforated metal for its application. The larger the holes the narrower are the bars. The general rule is that the thickness of the metal should not be greater than the size of the holes or the width of the bars. Following this guideline can avoid tool failure during processing.

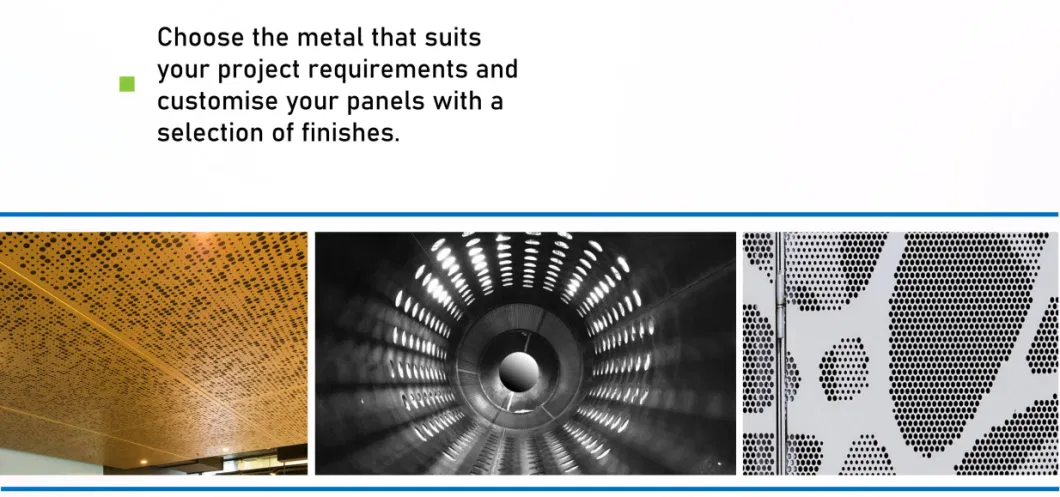

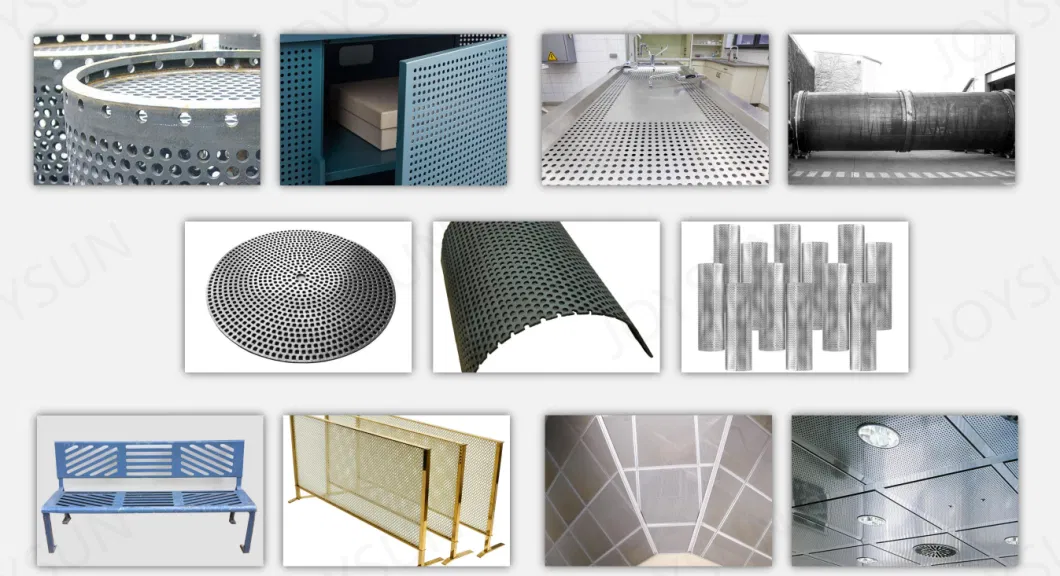

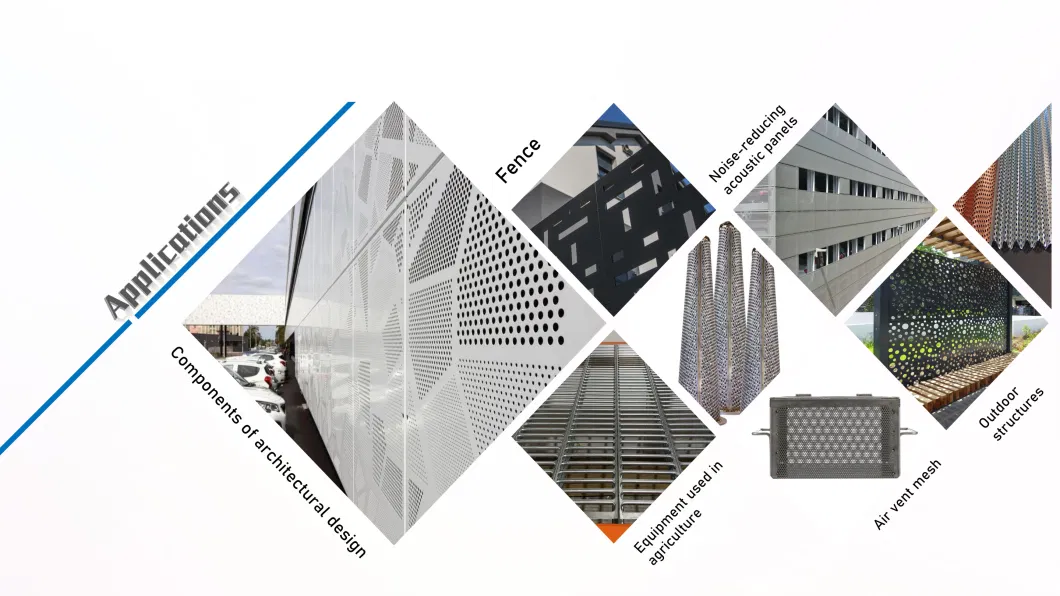

Perforated Steel Applications

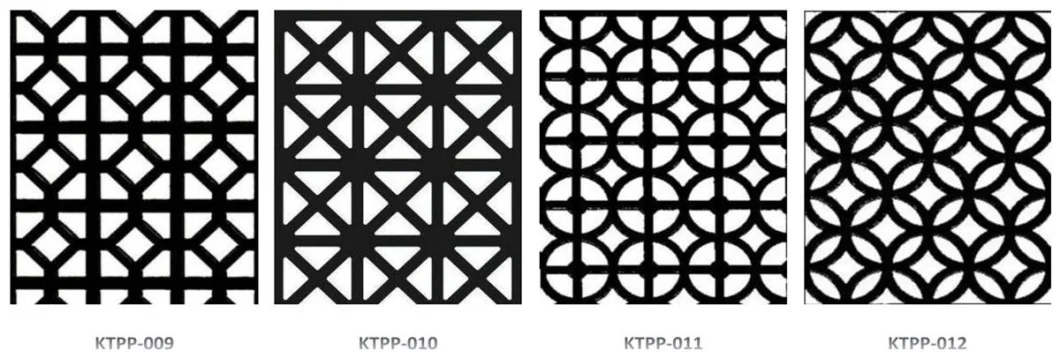

As a result of our flexible customisation options, we can provide mild steel perforated mesh in virtually any shape or size. Using our equipment and expertise, we are able to provide solutions that are tailored precisely to the specifications and needs of each project. Whether you are looking for something practical or for a visually appealing addition, our experts will be able to help. We offer a variety of services, including but not limited to:

- Components of architectural design

- Equipment used in agriculture

- Guards, grilles, and screens

- Noise-reducing acoustic panels

- Rodent proofing vent mesh

- Air vent mesh

- Vehicle construction

- Panels

- Framework

- Sheds

- Outdoor structures

- Trailer parts

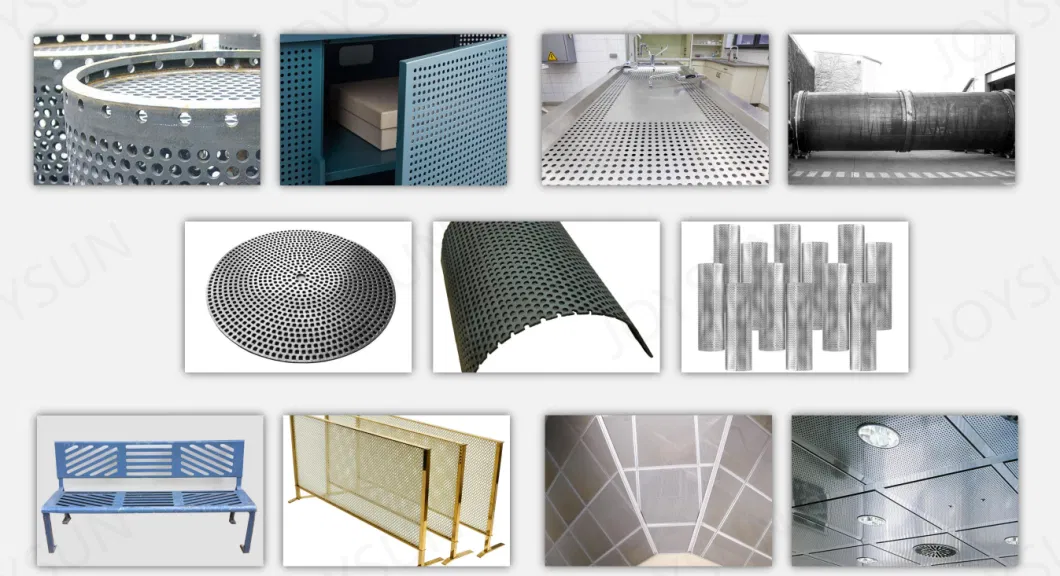

Products Made from Perforated Metals

There are a wide variety of applications for perforated metals. They find use in industrial settings as well as homes and offices. From building construction and design to filtration units for pharmaceutical production, perforated metals have been an essential part of producing products and providing a pleasing appearance.

Products Made from Perforated Metals

There are a wide variety of applications for perforated metals. They find use in industrial settings as well as homes and offices. From building construction and design to filtration units for pharmaceutical production, perforated metals have been an essential part of producing products and providing a pleasing appearance.

Our Service

These perforated metal sheets are offered here in small sizes to suit all requirements. We also offer this metal mesh in full 2 x 1 metre and 2.44 x 1.22 metre panels. These large panels are sent on pallets and we will check your unloading capacity before shipping. In brief, our speciality is rapid, fuss free transactions of all sizes. If you are looking to buy metal in small amounts then this is the place for you. We cut this metal on our ultra powerful industrial guillotine. We are always happy to help in any way that we are able to. Ask about our cutting service and a quick delivery. Thank you for checking out our product.

Our Service

These perforated metal sheets are offered here in small sizes to suit all requirements. We also offer this metal mesh in full 2 x 1 metre and 2.44 x 1.22 metre panels. These large panels are sent on pallets and we will check your unloading capacity before shipping. In brief, our speciality is rapid, fuss free transactions of all sizes. If you are looking to buy metal in small amounts then this is the place for you. We cut this metal on our ultra powerful industrial guillotine. We are always happy to help in any way that we are able to. Ask about our cutting service and a quick delivery. Thank you for checking out our product.

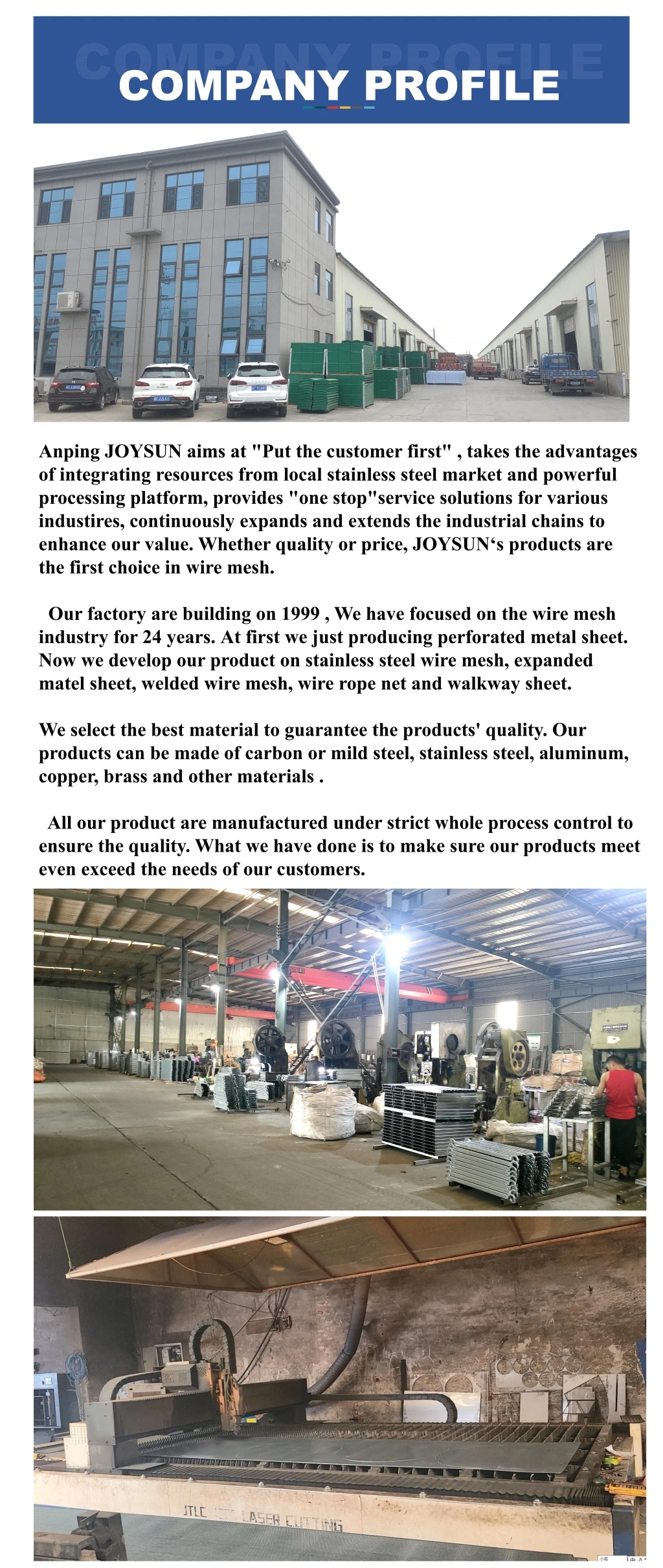

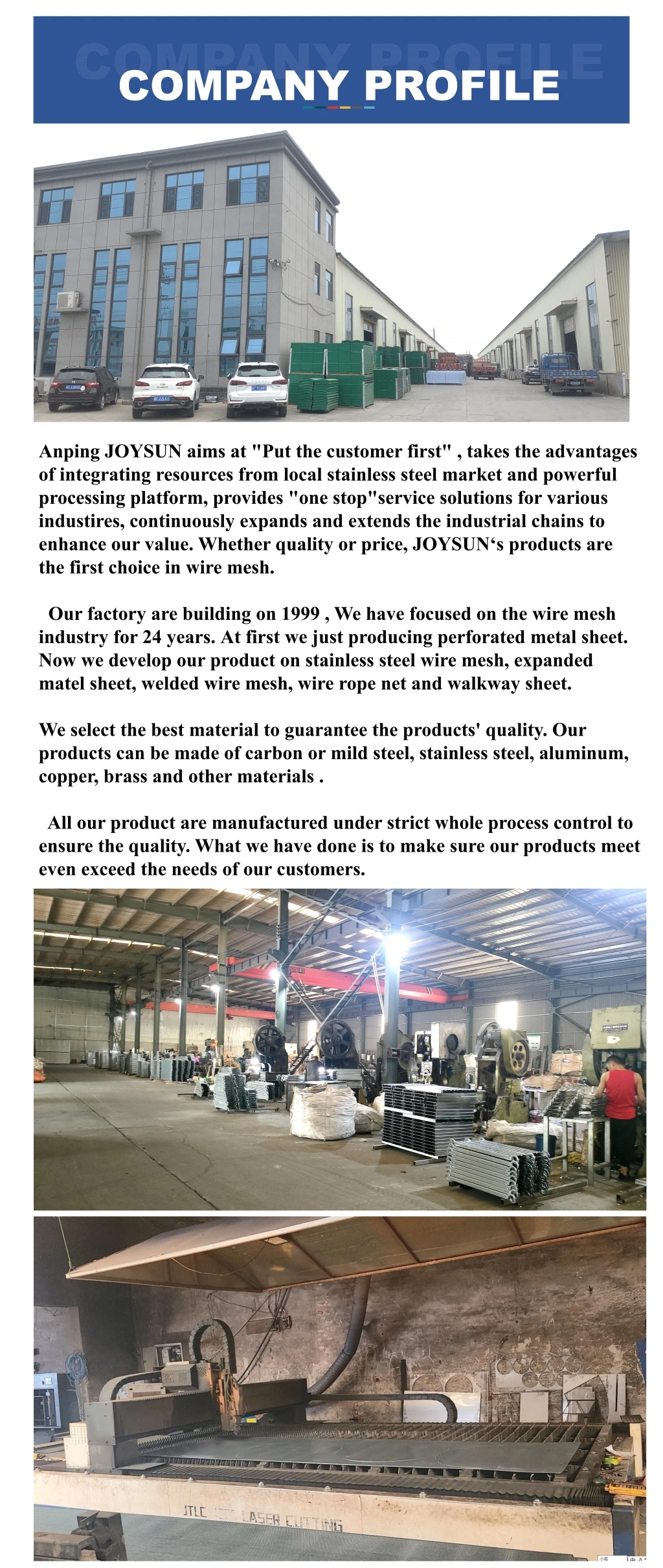

Company Profile

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!