Product Description:

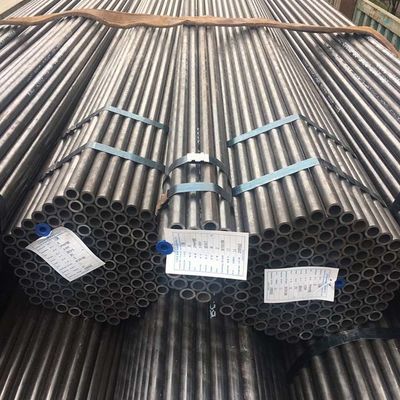

Stainless Steel Pipe

This is a type of pipe made from high quality stainless steel, designed to withstand various industrial and commercial applications. With its excellent corrosion resistance properties, it is commonly used in environments where regular pipes may rust or corrode.

Material Grade

The Stainless Steel Pipe is available in three different material grades: TP304, TP304L, and TP304H. These grades are known for their durability, strength, and resistance to corrosion.

Products

The Stainless Steel Pipe is a versatile product that can be used in a variety of applications. It is commonly used in industries such as oil and gas, chemical processing, and food and beverage. It is also used in construction, plumbing, and transportation.

Thickness

The Stainless Steel Pipe is available in a range of thicknesses, from 0.3mm to 60mm. This allows for flexibility in its use, as it can be used for both light and heavy-duty applications.

Az Coating

The Stainless Steel Pipe is coated with Az, a type of zinc coating, to provide additional protection against corrosion. The Az coating has a weight range of 30-150g/m2, making it suitable for a wide range of environments.

Size

The Stainless Steel Pipe is available in a variety of sizes, ranging from 10mm to 120mm in diameter. This range of sizes makes it suitable for various applications, from small plumbing projects to large industrial installations.

Polished Stainless Pipe

The Stainless Steel Pipe is available in a polished finish, giving it a sleek and professional appearance. This makes it suitable for use in applications where aesthetics are important, such as in architecture and interior design.

Conclusion

The Stainless Steel Pipe is a durable, versatile, and corrosion-resistant product that is suitable for a wide range of applications. Its various material grades, thicknesses, coatings, and sizes make it a popular choice in many industries. Its polished finish also adds to its aesthetic appeal, making it a practical and stylish option for various projects.

| Category |

Stainless steel tube pipe |

| Material |

ASTM : 200 series : S20100 / 201 , S20200 / 202

300 series : S30100 / 301 , S30400 / 304 , S30403 / 304L , S31008 / 310S , S31600 / 316 , S31603 / 316L , S31635 / 316Ti , S32100 / 321

Duplex series : S32205 / 2205 , S32750 / 2507

400 series : S43000 , S41000 / 410 , S42000 / 420 ;

900 series : 904L

JIS : 200 series : SUS201 , SUS202

300 series : SUS301 , SUS304 , SUS304L , SUS310S , SUS316 , SUS316L , SUS316Ti , SUS321

400 series : SUS430 , SUS410 , SUS420J1 , SUS420J2 ;

900 series : 904L

DIN EN / BS EN / NF EN :

200 series : 1.4372 1.4373

300 series : 1.4319 , 1.4301 , 1.4306 , 1.4845 , 1.4401 , 1.4404 , 1.4571 , 1.4541

400 series : 1.4016 , 1.4006 , 1.4021 , 1.4028 ;

900 series : 904L

Duplex series : 1.4410 |

| Wall Thickness |

5S/10S/40S/STD/60S/XS/XXS |

| Size |

DN15-DN500 and customized sizes . |

| Technology |

Welded / Seamless |

| Surface Treatment |

ASTM : No.1 , No.2D , No.2B , Bright Annealed , No. 3 , No. 4 , No.6 , No. 7 , No. 8 , TR ;

JIS : No.1 , No.2D , No.2B , No. 3 , No. 4 , #240 , #320 , #400 , BA , HL

GB : 1U , 1C , 1E , 1D , 2E , 2D , 2B , BA , 3# , 4# , 6# , 7# , 8# , TR , HL

EN : 1C , 1E , 1D , 2C , 2E , 2D , 2B , 2R , 1G , 2G , 1J , 2J , 1K , 2K , 1P , 2P , 2F

Others : Colored , Brush , Polishing , Etch , Embossed , Hammer , PVD Coating ,Color Mirror , Color Brush , Color Etch , Color Embossed , Color Hammer ...... |

| MOQ |

1T |

| Trade Term |

EXW , FOB , CIF , CFR etc . |

| Payment Term |

T/T , L/C , Cash , etc . |

| Delivery Time |

7-10 days |

| Certifications |

SGS, ISO, etc . |

| Advantages |

Attracting Price; High surface quality; First-rate service; Customer satisfaction is our eternal pursuit . |

200 Series

| Grade |

Chemical Composition |

| ASTM |

C≤ |

Si≤ |

Mn≤ |

P≤ |

S≤ |

Ni |

Cr |

Mo |

N |

Cu |

S20100

201 |

0.15 |

1.00 |

5.50-7.50 |

0.06 |

0.03 |

3.50-5.50 |

16.00-18.00 |

------- |

0.25 |

------- |

S20200

202 |

0.15 |

1.00 |

7.50-10.00 |

0.06 |

0.03 |

4.00-6.00 |

17.00-19.00 |

------- |

0.25 |

------- |

300 Series

| Grade |

Chemical Composition % |

| ASTM |

C≤ |

Mn≤ |

P≤ |

S≤ |

Si≤ |

Cr |

Ni |

Mo |

N |

Cu |

Others |

S30100

301 |

0.15 |

2.00 |

0.045 |

0.030 |

1.00 |

16.0-18.0 |

6.0-8.0 |

----- |

0.10 |

----- |

----- |

S30400

304 |

0.070 |

2.00 |

0.045 |

0.030 |

0.75 |

17.5-19.5 |

8.0-10.5 |

----- |

0.10 |

----- |

|

S30403

304L |

0.030 |

2.00 |

0.045 |

0.030 |

0.75 |

17.5-19.5 |

8.0-12.0 |

----- |

0.10 |

----- |

|

S30908

309S |

0.08 |

2.00 |

0.045 |

0.030 |

0.75 |

22.0-24.0 |

12.0-15.0 |

----- |

----- |

----- |

|

S31008

310S |

0.08 |

2.00 |

0.045 |

0.030 |

1.50 |

24.0-26.0 |

19.0-22.0 |

----- |

----- |

----- |

|

S31600

316 |

0.08 |

2.00 |

0.045 |

0.030 |

0.75 |

16.0-18.0 |

10.0-14.0 |

2.0-3.0 |

0.10 |

----- |

|

S31603

316L |

0.030 |

2.00 |

0.045 |

0.030 |

0.75 |

16.0-18.0 |

10.0-14.0 |

2.0-3.0 |

0.10 |

----- |

|

S31635

316Ti |

0.08 |

2.00 |

0.045 |

0.030 |

0.75 |

16.0-18.0 |

10.0-14.0 |

2.0-3.0 |

0.10 |

----- |

Ti 5*(C+N) min, 0.70 max .

Nb 10*C min , 1.10 max . |

S32100

321 |

0.08 |

2.00 |

0.045 |

0.030 |

0.75 |

17.0-19.0 |

9.0-12.0 |

----- |

0.10 |

----- |

|

400 Series

| Grade |

Chemical Composition % |

| ASTM |

C≤ |

Mn≤ |

P≤ |

S≤ |

Si≤ |

Cr |

Ni |

S43000

430 |

0.12 |

1.00 |

0.04 |

0.030 |

1.00 |

16.0-18.0 |

0.75 |

Equivalents of Various Grades

| ASTM |

JIS |

DIN/BS/NF EN |

GB/T |

ISO |

S20100

201 |

SUS201 |

X12CrMnNiN17-7-5

1.4372 |

12Cr17Mn6Ni5N

(1Cr17Mn6Ni5N) |

X12CrMnNiN17-7-5 |

S20200

202 |

SUS202 |

X12CrMnNi18-9-5

1.4373 |

12Cr18Mn9Ni5N

(1Cr18Mn8Ni5N) |

----------- |

S30100

301 |

SUS301 |

X5CrNi17-7

1.4319 |

12Cr17Ni7

(1Cr17Ni7) |

X5CrNi17-7 |

S30400

304 |

SUS304 |

X5CrNi18-10

1.4301 |

06Cr19Ni10

(0Cr18Ni9) |

X5CrNi18-9 |

S30403

304L |

SUS304L |

X2CrNi19-11

1.4306 |

022Cr19Ni10

(00Cr19Ni10) |

X2CrNi19-11 |

S30900

309 |

SUH309 |

X12CrNi23-13

1.4833 |

16Cr23Ni13

(2Cr23Ni13) |

X12CrNi23-13 |

S30908

309S |

SUS309S |

X12CrNi23-13

1.4833 |

06Cr23Ni13

(0Cr23Ni13) |

X12CrNi23-13 |

S31000

310 |

SUH310 |

X15CrNiSi25-21

1.4841 |

20Cr25Ni20

(2Cr25Ni20) |

X8CrNi25-21 |

S31008

310S |

SUS310S |

X8CrNi25-21

1.4845 |

06Cr25Ni20

(0Cr25Ni20) |

X8CrNi25-21 |

S31600

316 |

SUS316 |

X5CrNiMo17-12-2

1.4401 |

06Cr17Ni12Mo2

(0Cr17Ni12Mo2) |

X5CrNiMo17-12-2 |

S31603

316L |

SUS316L |

X2CrNiMo17-12-2

1.4404 |

022Cr17Ni12Mo2

(00Cr17Ni14Mo2) |

X2CrNiMo17-12-2 |

S31635

316Ti |

SUS316Ti |

X6CrNiMoTi17-12-2

1.4571 |

06Cr17Ni12Mo2Ti

(0Cr18Ni12Mo3Ti) |

X6CrNiMoTi17-12-2 |

S32100

321 |

SUS321 |

X6CrNiTi18-10

1.4541 |

06Cr18Ni11Ti

(0Cr18Ni10Ti) |

X6CrNiTi18-10 |

S41008

410S |

SUS410S |

X6Cr13

1.4000 |

06Cr13

(0Cr13) |

X6Cr13 |

S41000

410 |

SUS410 |

X12Cr13

1.4006 |

12Cr13

(1Cr13) |

X12Cr13 |

| ----------- |

SUS410J1 |

----------- |

12Cr13

(1Cr13) |

----------- |

S42000

420 |

SUS420J1 |

X20Cr13

1.4021 |

13Cr13Mo

(1Cr13Mo) |

X20Cr13 |

S42000

420 |

SUS420J2 |

X30Cr13

1.4028 |

30Cr13

(3Cr13) |

X30Cr13 |

| S43000 |

SUS430 |

X6Cr17

1.4016 |

10Cr17

(1Cr17) |

X6Cr17 |

S32205

2205 |

----------- |

X2CrNiMoN22-5-3

1.4462 |

022Cr23Ni5Mo3N |

X2CrNiMoN22-5-3 |

S32750

2507 |

----------- |

X2CrNiMoN25-7-4

1.4410 |

022Cr25Ni7Mo4N |

X2CrNiMoN25-7-4 |

| 904L |

SUS890L |

X1NiCrMoCu25-20-5

1.4539 |

00Cr20Ni25Mo4.5Cu |

----------- |

ASTM : No.1 , No.2D , No.2B , Bright Annealed , No. 3 , No. 4 , No.6 , No. 7 , No. 8 , TR ;

JIS : No.1 , No.2D , No.2B , No. 3 , No. 4 , #240 , #320 , #400 , BA , HL

GB : 1U , 1C , 1E , 1D , 2E , 2D , 2B , BA , 3# , 4# , 6# , 7# , 8# , TR , HL

EN : 1C , 1E , 1D , 2C , 2E , 2D , 2B , 2R , 1G , 2G , 1J , 2J , 1K , 2K , 1P , 2P , 2F

Others : Colored , Brush , Polishing , Etch , Embossed , Hammer , PVD Coating ,Color Mirror , Color Brush , Color Etch ,

ASTM : No.1 , No.2D , No.2B , Bright Annealed , No. 3 , No. 4 , No.6 , No. 7 , No. 8 , TR ;

JIS : No.1 , No.2D , No.2B , No. 3 , No. 4 , #240 , #320 , #400 , BA , HL

GB : 1U , 1C , 1E , 1D , 2E , 2D , 2B , BA , 3# , 4# , 6# , 7# , 8# , TR , HL

EN : 1C , 1E , 1D , 2C , 2E , 2D , 2B , 2R , 1G , 2G , 1J , 2J , 1K , 2K , 1P , 2P , 2F

Others : Colored , Brush , Polishing , Etch , Embossed , Hammer , PVD Coating ,Color Mirror , Color Brush , Color Etch ,

Color Embossed , Color Hammer ......

carries a wide range of stainless steel plate products, enabling us to quickly and affordably

fulfill client material requests. Whether you need a standard sheet or a custom diamond tread sheet and expanded metal product,

we have the inventory and sourcing capabilities to get the job done.

Product processing

(1) Cut Type:

Plasma cutting, laser cutting, water cutting,etc.

(2) other processing:shearing, bending, slitting, welding, punching, gouging,etc

More Stainless steel Product.Carton Steel Products.Aluminum products.Galvanized Steel Products and etc

Our Company also Sell stainless steel sheet, Stainless Steel Coil, Sheet, Strip, tube,and All Kind Of Bars, and

Carton Steel

Products.Aluminum products.Galvanized Steel Products etc .good prices 316l Stainless steel plate.304 321 Stainless steel plate

Company Profile

professional manufacturer engaged in researching, processing and production and sales for

steel sheet , steel coil , steel pipe , steel profiles , steel bars etc . The material includes galvanized, PPGI, carbon steel , alloy ,

stainless steel, aluminium , copper and so on . Our company's annual sales volume exceeded 500,000 tons , have more than

800 kinds of specifications. Our factory equipped with advanced equipment including laser cutting machine, decoiler machine ,

slitting machine , flying shear machine, Hairline processing machine, polishing machine, folding plate machine, ERW machine ,

packing machine etc. We have a strict system of quality control,SGS testing or other third party testing is welcome. Our products

are in great demand both at domestic and abroad by virtue of excellent product quality and competitive price. Our products are

widely used in the field of tableware, kitchen ware, medical apparatus and instruments, household appliances, auto parts,

construction and decoration , petrochemical industry etc. Our Company has been in steel products and exporting for more than

20 years . And our clients are all over the world. is just the long term reliable steel supplier you are looking for !

Welcome know more about our company

1.Q: Can we visit your factory?

- A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

2.Q: Can provide OEM/ODM service?

-A: Yes. Please feel free to contact us for more details discuss.

3.Q: How is your Payment Term?

-A:We prefer TT, L/C, Western Union, etc.

4.Q: Can you provide sample?

-A: Yes!we can send samples to all parts of the world, our samples are free, but customers need to bear the courier costs.

5.Q.Surface coating

A: Antirusted painting, varnish painting, galvanized, 3LPE, 3PP,Zinc oxide yellow primer,Zinc phosphate primer and as per

customers' request.

6.Q:Why choose our company ?

-A:(1)We are specialized in this industry for more than 20 years (2) We are full stock (3)we have ourselves processing factory

7.Q: What's the MOQ ?

-A: 1 Ton is OK.

8.Q: What's your delivery time ?

-A:Regular lead time is 15 to 30 days after receiving deposit

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!