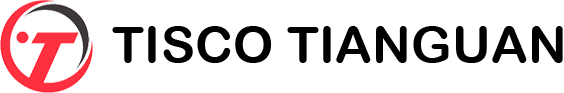

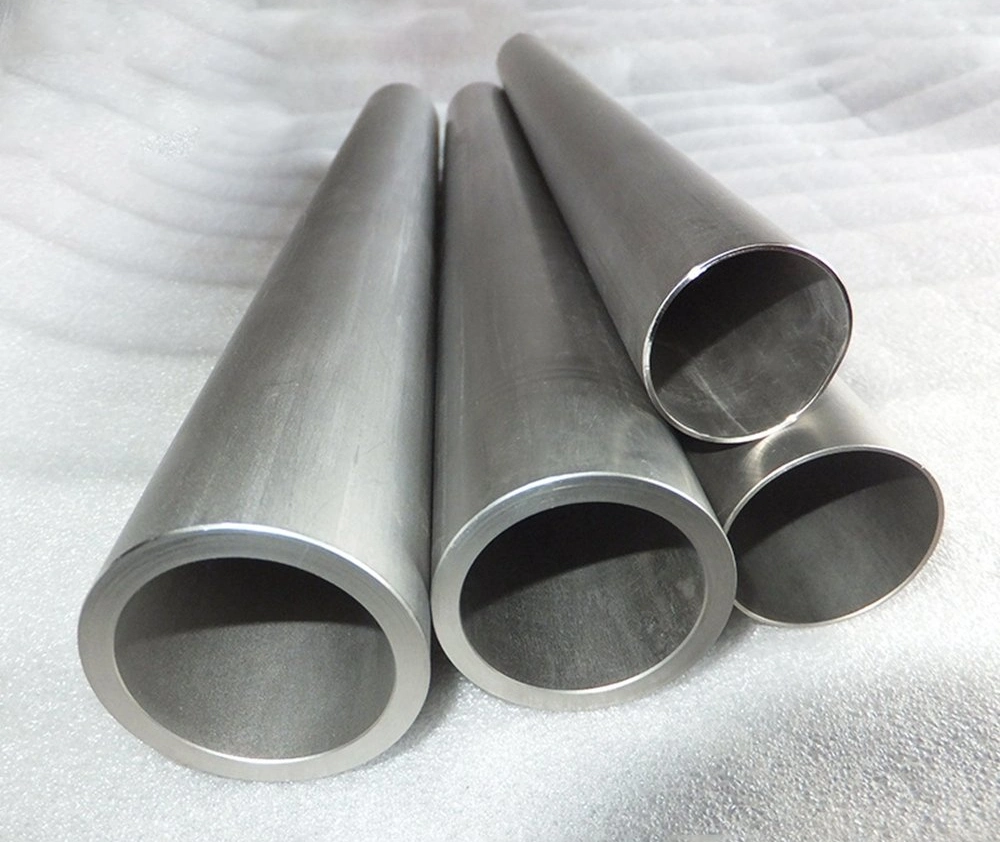

Monel 400 Seamless Tubing Uns N04400 Welded Tubing Fitting K500 Pipe

Monel 400 is a nickel-copper alloy (about 67% Ni - 23% Cu) that is resistant to sea water and steam at high temperatures as well as to salt and caustic solutions. Alloy 400 is a solid solution alloy that can only be hardened by cold working. This nickel alloy exhibits characteristics like good corrosion resistance, good weldability and high strength. A low corrosion rate in rapidly flowing brackish or seawater combined with excellent resistance to stress-corrosion cracking in most freshwaters, and its resistance to a variety of corrosive conditions led to its wide use in marine applications and other non-oxidizing chloride solutions. This nickel alloy is particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated. As would be expected from its high copper content, alloy 400 is rapidly attacked by nitric a cid and ammonia systems. Monel 400 has great mechanical properties at subzero temperatures, can be used in temperatures up to 1000° F, and its melting point is 2370-2460° F. However, alloy 400 is low in strength in the annealed condition so, a variety of tempers may be used to increase the strength.

Features:

* Resistant to seawater and steam at high temperatures

* Excellent resistance to rapidly flowing brackish water or seawater

* Excellent resistance to stress corrosion cracking in most freshwaters

* Particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated

* Offers some resistance to hydrochloric and sulfuric acids at modest temperatures and concentrations, but is seldom the material of choice for these acids

* Excellent resistance to neutral and alkaline salt

* Resistance to chloride induced stress corrosion cracking

* Good mechanical properties from sub-zero temperatures up to 1020° F

* High resistance to alkalis

Applications:

* Valves, pumps, shafts, fittings, and fasteners

* Industrial heat exchangers

* Chlorinated solvents

* Crude oil distillation towers

* Marine engineering

* Chemical and hydrocarbon processing equipment

* Gasoline and freshwater tanks

* Crude petroleum stills

* De-aerating heaters

* Boiler feed water heaters and other heat exchangers

Monel 400 International Brand

|

|

|

USA

|

GE

|

UK

|

FR

|

|

|

UNS

|

SEW VDIUV

|

BS

|

AFNOR

|

|

Monel 400

|

N04400

|

W.Nr.2.4360 NiCu30Fe

|

NA 12

|

Nu 30

|

|

|

|

|

Tensile Strength

(Rm N/mm2)

|

Yield strength

(RP0.2N/mm2)

|

|

|

|

|

|

|

|

|

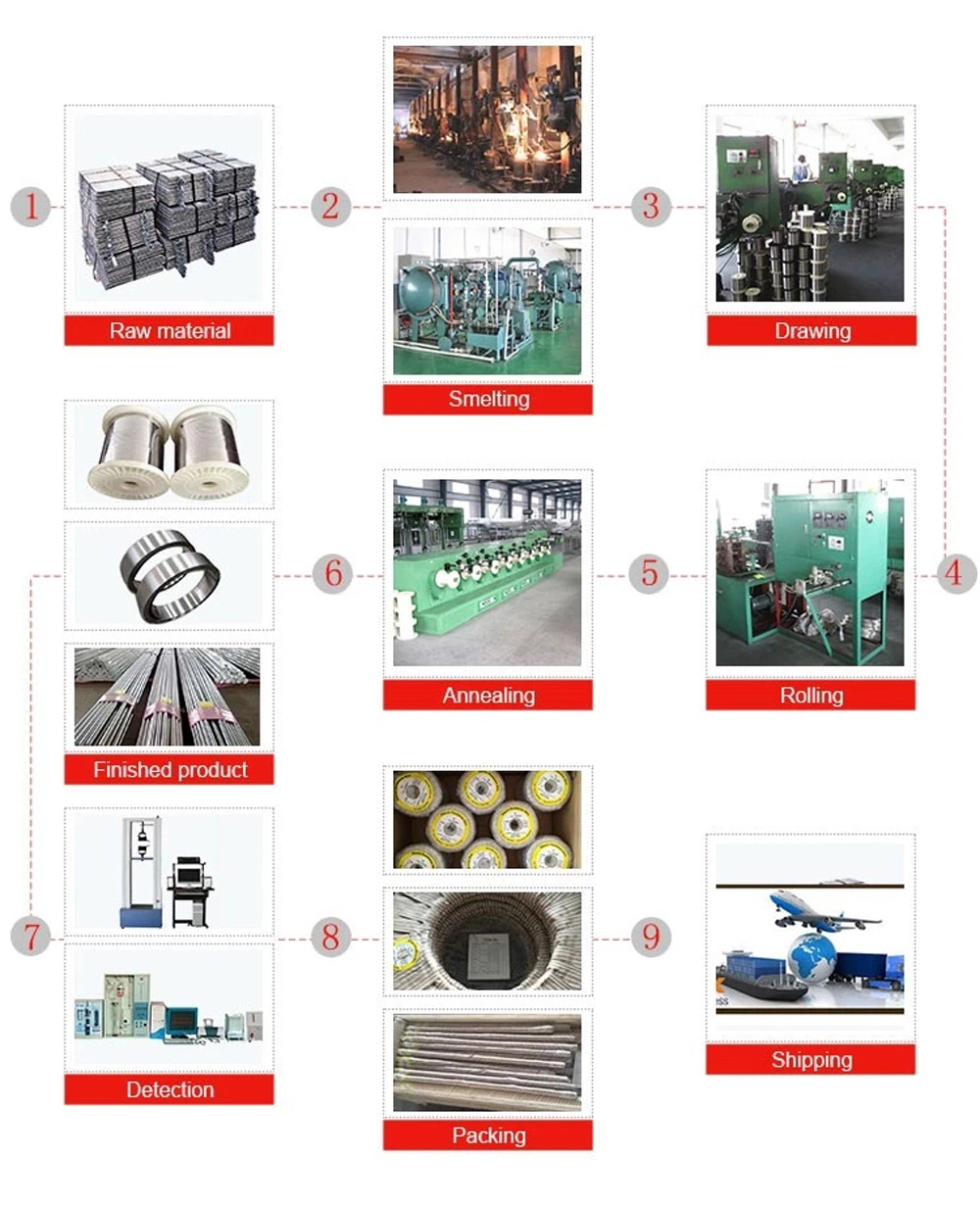

Our company Principle is " Quality first, Customer first".

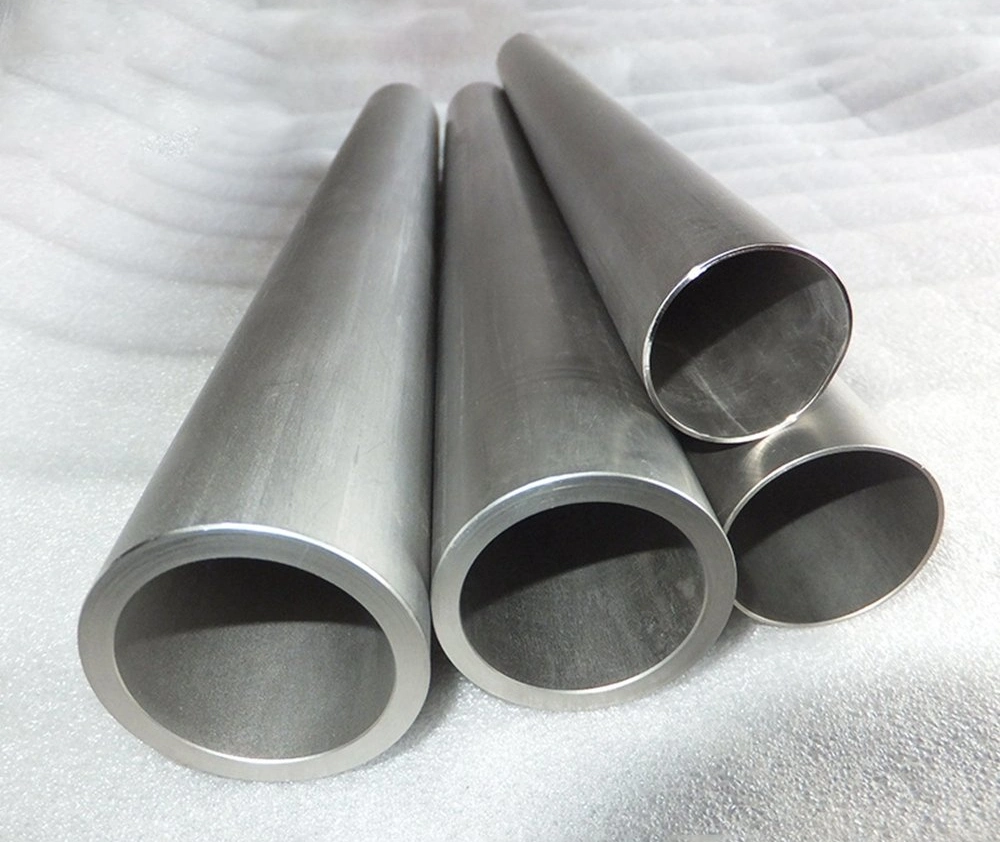

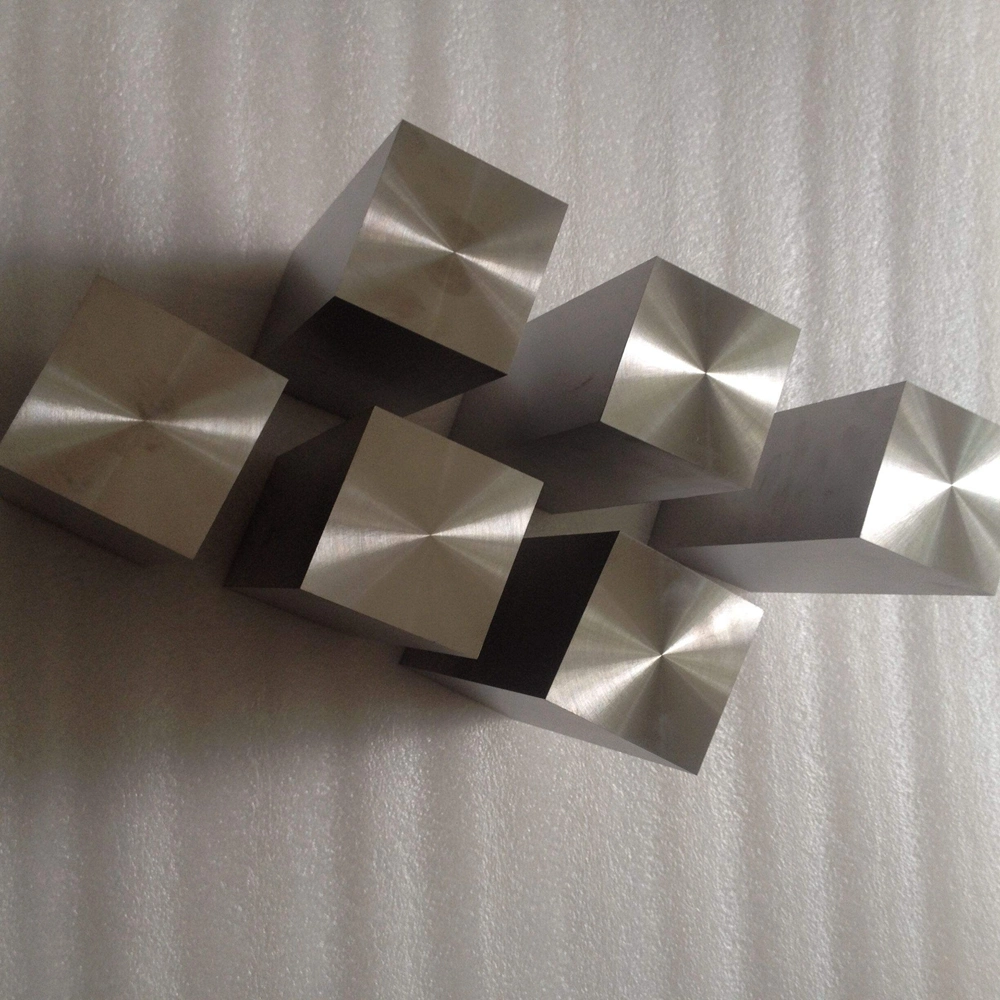

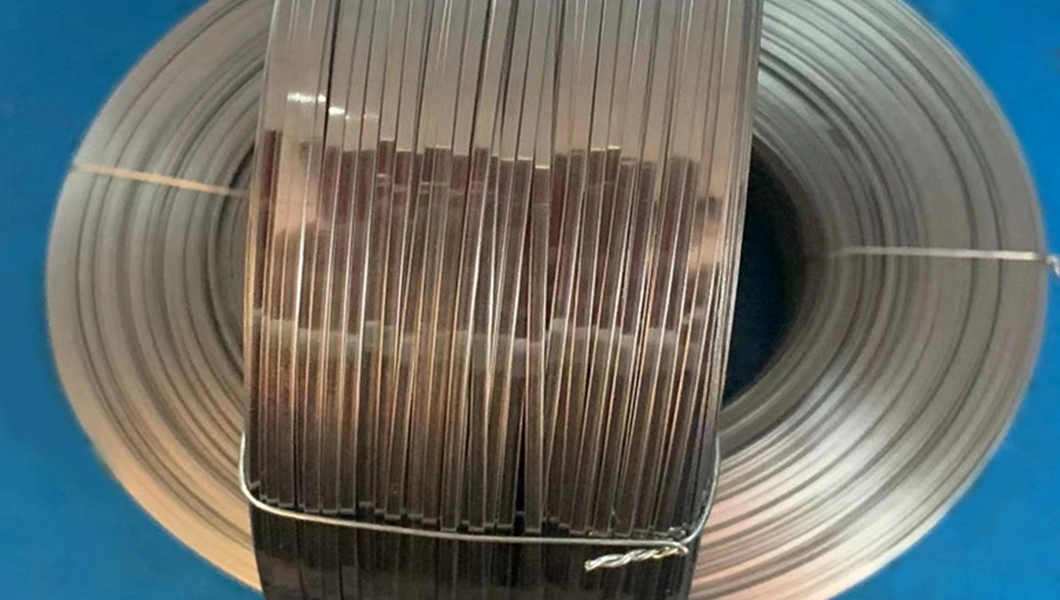

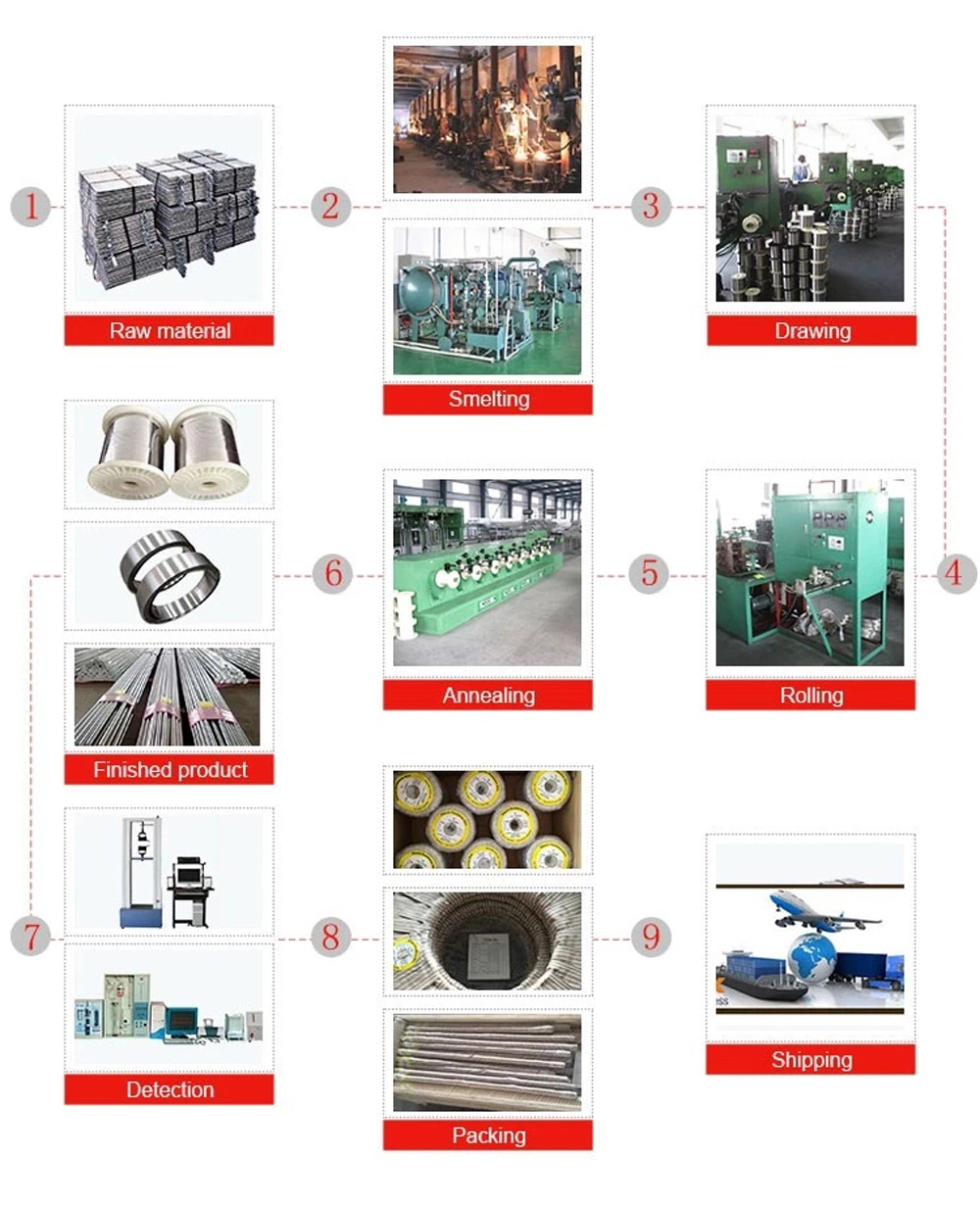

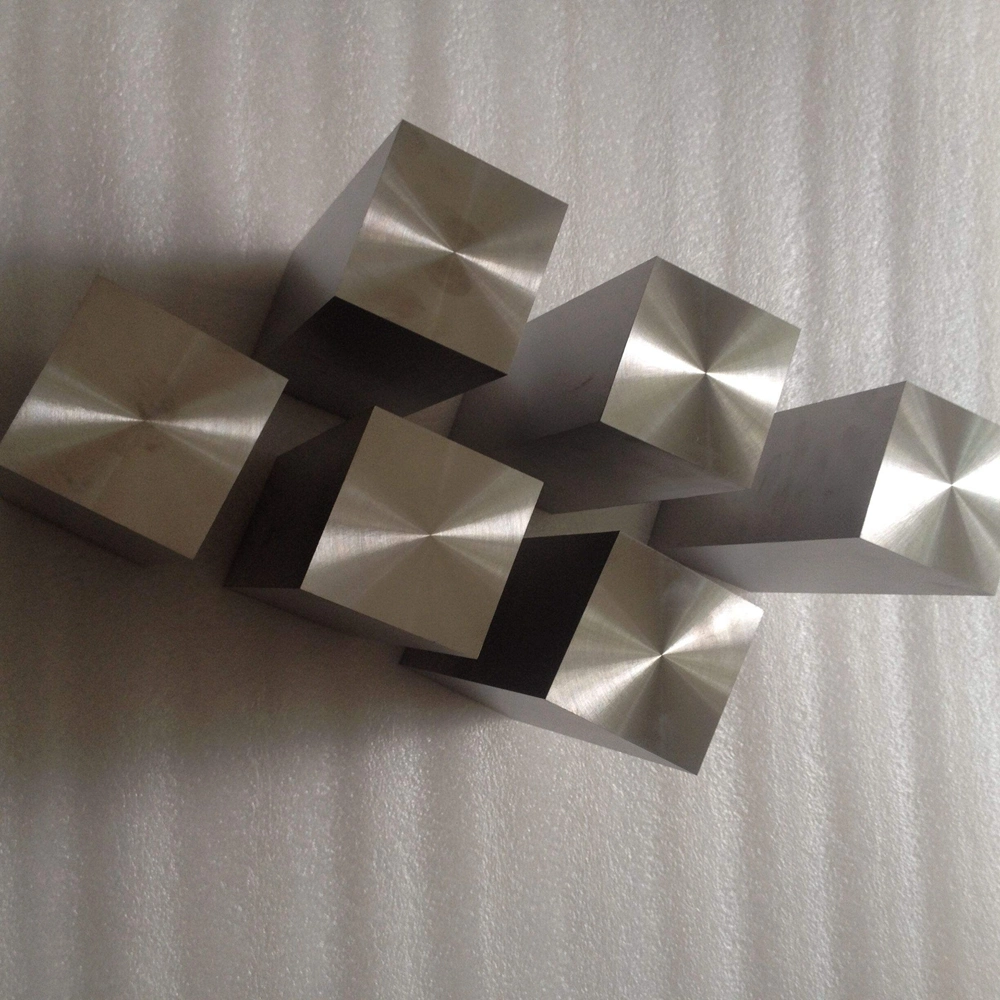

was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples.

2, We can provide the products within a week after payment.

3, Wecan provide sample of the products customer need.

4, We always insist on "Quality first, Customer first" as our business philosophy.

Question: Are you a trading company or manufacturer?

Answer: We're manufacturer.

Question2: Could you help to design the product?

Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome.

Question: Could you supply samples?

Answer: Yes, wecould supply samples according to your requirement.

Question: could we visit your factory?

Answer: Sure, factory visit is warmly welcome.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!