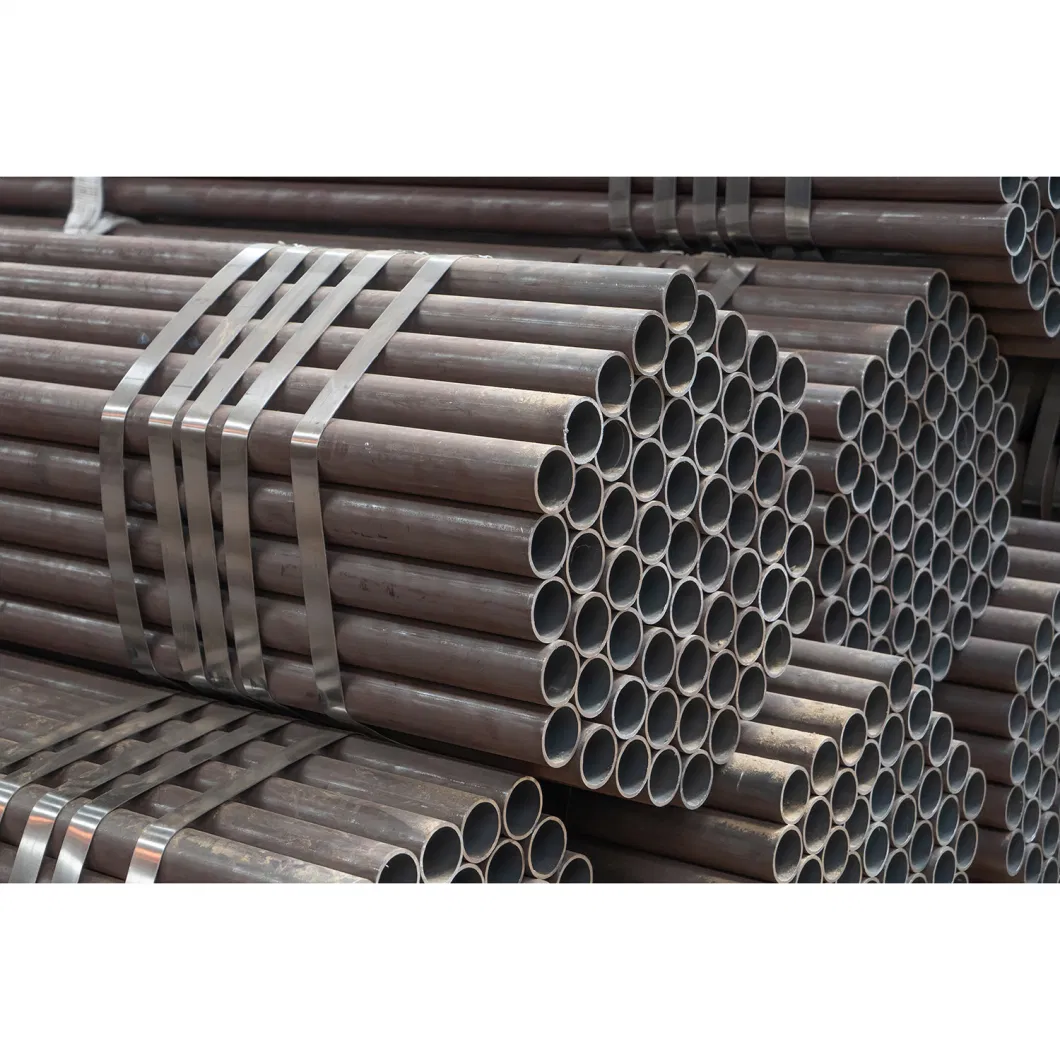

Q235 A53 Carbon Steel Seamless Pipe Seamless Steel Tube ERW Steel Tube ASTM API 5L ERW Steel Pipe

Product Description:

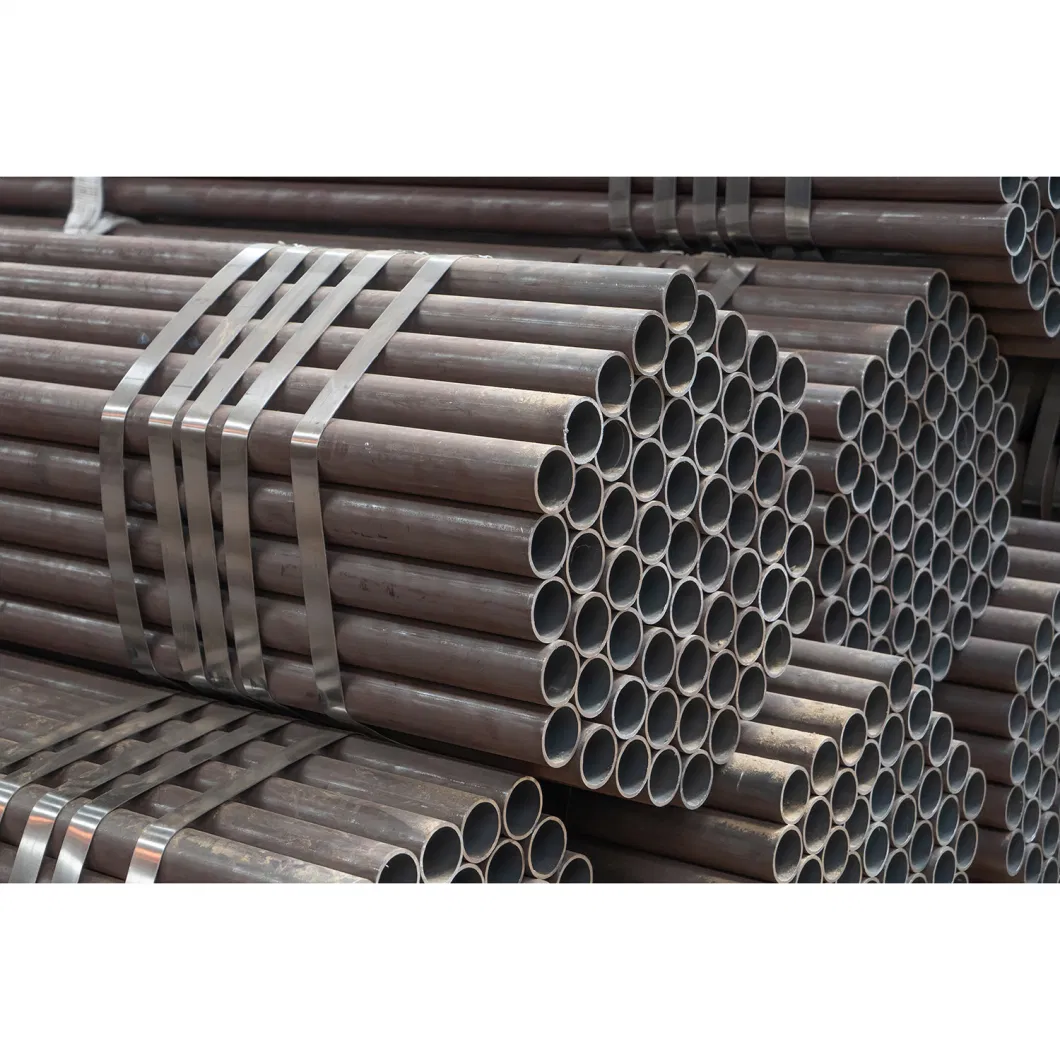

Carbon Steel Pipe

Carbon steel pipe is a type of steel pipe made of carbon steel, a material known for its strength, durability, and cost-effectiveness. It is widely used in various industries, such as construction, oil and gas, and agriculture, due to its lasting performance and versatility. With its excellent mechanical properties and high resistance to corrosion, carbon steel pipe is an ideal choice for a wide range of applications.

Feature: Lasting Performance

One of the key features of carbon steel pipe is its lasting performance. Made from high-quality carbon steel, it is able to withstand extreme temperatures, pressures, and harsh environments. This makes it a reliable choice for long-term use, reducing the need for frequent replacements and maintenance.

Processing Service

Carbon steel pipe can be processed in various ways to meet different requirements. Some of the common processing services include welding, punching, cutting, and bending. These processes can be carried out on both seamless and welded carbon steel pipes, depending on the specific needs of the project.

Tolerance: ±1%

With a tolerance of ±1%, carbon steel pipe offers a high level of dimensional accuracy. This ensures a precise fit and proper alignment, resulting in a more efficient and effective installation. The tight tolerance also helps to reduce the risk of leaks and other potential issues.

Third-Party Inspection

To ensure the quality and reliability of carbon steel pipe, it is often subjected to third-party inspection by reputable organizations such as SGS, BV, TUV, ABS, DNV, LR, GL, and ASME. These inspections involve thorough testing and evaluation of the product to ensure it meets the required standards and specifications.

Type: Seamless / Welded

Carbon steel pipe is available in two main types: seamless and welded. Seamless carbon steel tubing is made from a solid round billet and does not have any welded seams, making it strong and leak-proof. On the other hand, welded carbon steel pipe is made from a flat strip of steel that is formed into a tube and welded along the seam. This type of pipe is more cost-effective and suitable for less demanding applications.

Spiral Welded Carbon Steel Pipe

Spiral welded carbon steel pipe is a type of welded pipe produced by forming a spiral shape with a strip of steel. This type of pipe is commonly used in larger diameter applications, such as oil and gas pipelines, due to its strength and ability to withstand high pressure.

Seamless Carbon Steel Tubing

Seamless carbon steel tubing is a type of seamless pipe that is made from carbon steel. It is known for its high strength and resistance to corrosion, making it suitable for a wide range of industrial applications, including oil and gas, chemical processing, and power generation.

Carbon Steel Hollow Pipe

Carbon steel hollow pipe, also known as hollow structural sections (HSS), is a type of pipe that is formed into a hollow cross-section. It is commonly used in structural applications, such as building frames and bridges, due to its high strength-to-weight ratio and aesthetic appeal.

Basic Info.

Usage

Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Food/Beverage/Dairy Products, Machinery Industry, Chemical Industry, Mining, Construction & Decoration, Special Purpose

Transport Package

Standard Sea Worth Packing

Production Capacity

500000

Product Description

High Precision ASTM A106 DIN2391 Cold Rolled and Cold Drawn Seamless Steel Pipe Tube

|

item

|

astm a106 gr.b sae 1020 seamless carbon steel pipe seamless tube with price per meter for chemical / transport

|

|

Standard

|

BS EN10296, GB 5310-1995, ASTM A106-2006, BS EN10025, BS EN 10297

|

|

Thickness

|

2mm - 200mm

|

|

Section Shape

|

Round

|

|

|

|

|

Place of Origin

|

API

|

|

Application

|

Structure Pipe

|

|

Technique

|

Hot Rolled

|

|

Certification

|

API

|

|

Surface Treatment

|

galvanized

|

|

Special Pipe

|

API Pipe

|

|

Alloy Or Not

|

Non-Alloy

|

|

Tolerance

|

±3%

|

|

Type

|

Seamless Steel Pipe

|

|

Processing Service

|

Bending, Welding, Decoiling, Punching, Cutting

|

FAQ

1. who are we?

start from 2008,sell to North America(13.00%),South America(11.00%),South Asia(10.00%),Africa(10.00%),Southern Europe(10.00%),Western Europe(6.00%),Domestic Market(5.00%),Northern Europe(5.00%),Central America(5.00%),Oceania(5.00%),Eastern Asia(5.00%),Southeast Asia(5.00%),Eastern Europe(5.00%),Mid East(5.00%).

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Steel Sheet,Steel Pipe,Steel Coil,steel bar,stainless steel bar

4. why should you buy from us not from other suppliers?

We manufacture steel products or steel structure for the Solar Mounting Steel Structure, Transmission & Distribution Steel Structures (Towers & Poles) , Construction, Industrial, Scaffolding and Greenhouse Construction. xinpeng special steel was founded

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW,DDP,DDU;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union;

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!