Professional Manufacturer Smls Pipe API 5L / ASTM A106 Gr. B / A53 Gr. B Sch40 Sch80

Product Description:

Carbon Steel Pipe

The carbon steel pipe is a type of steel pipe that is commonly used in a variety of industries, including construction, oil and gas, and water transmission. It is known for its strength, durability, and versatility, making it a popular choice for many applications.

Product Overview

The carbon steel pipe is made from carbon steel, a type of steel that contains carbon as the main alloying element. It is available in different sizes, shapes, and grades to meet the specific requirements of different industries.

Features

- Lasting Performance: The carbon steel pipe is known for its long-lasting performance, making it a reliable choice for various applications.

- High Strength: Due to its high carbon content, the carbon steel pipe has excellent strength and can withstand high pressure and heavy loads.

- Corrosion Resistance: The carbon steel pipe is coated with a layer of zinc or painted to protect it from corrosion, making it suitable for use in harsh environments.

- Versatility: The carbon steel pipe is available in different sizes, grades, and shapes, making it suitable for a wide range of applications.

Third Party Inspection

The carbon steel pipe undergoes thorough third-party inspections to ensure its quality and performance. Some of the recognized inspection agencies for carbon steel pipes include SGS, BV, TUV, ABS, DNV, LR, GL, and ASME.

Tolerance

The carbon steel pipe has a tolerance of ±1%, ensuring its accuracy and consistency in dimensions and thickness.

Process

The carbon steel pipe can be produced using two processes – hot rolled and cold rolled. The hot rolled process involves heating the steel above its recrystallization temperature and then shaping it into the desired form. The cold rolled process, on the other hand, involves rolling the steel at room temperature, resulting in a smoother and more precise finish.

Grade

The carbon steel pipe is available in different grades, including Q345, Q235, 20#, 10#, and Q195. These grades have varying levels of strength, ductility, and other properties, making them suitable for different applications.

Types of Carbon Steel Pipes

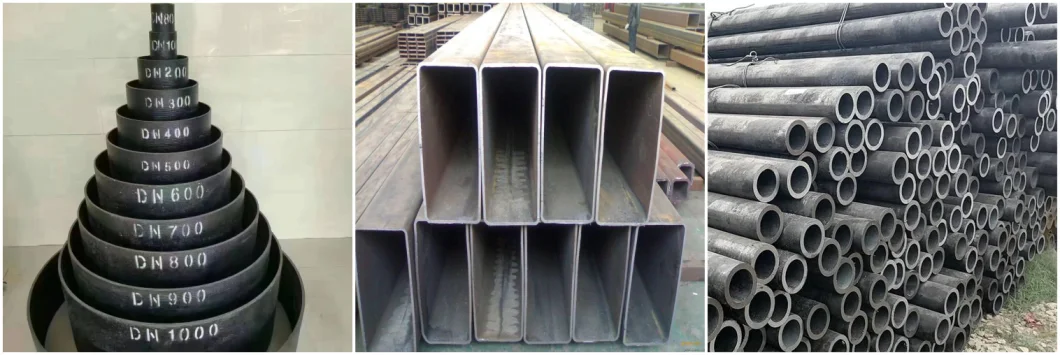

There are various types of carbon steel pipes available in the market, each with its unique characteristics and uses. Some of the most common types include:

- Carbon Steel Tube: This type of carbon steel pipe is hollow and cylindrical in shape, used for transporting fluids and gases.

- Spiral Welded Carbon Steel Pipe: As the name suggests, this type of carbon steel pipe is formed by spirally welding a strip of steel into a tube, making it suitable for high-pressure applications.

- Galvanized Carbon Steel Pipe: This type of carbon steel pipe is coated with a layer of zinc to protect it from rust and corrosion, making it ideal for outdoor use.

Conclusion

The carbon steel pipe is a versatile, high-strength, and long-lasting product that is widely used in various industries. Its various grades, types, and processes make it suitable for a wide range of applications, making it an essential component in modern infrastructure and construction.

Basic Info.

Usage

Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Food/Beverage/Dairy Products

Transport Package

Standard Sea Freight Packaging or According to Cus

Production Capacity

10000 Tons Per Month

Product Description

Product Description

|

Product name

|

Carbon Steel Pipe / Carbon Steel Tube

|

|

Standard

|

AiSi ASTM GB JIS

|

|

Grade

|

API A106 GR.B A53 Gr.B seamless steel pipe / ASTM A106 Gr.B A53 Gr.B steel tube

AP175-79, DIN2I5L , ASTM A106 Gr.B, ASTM A53 Gr.B,

ASTM A179/A192/A213/A210 /370 WP91, WP11,WP22

DIN17440, DIN2448,JISG3452-54

GB/T8162/T8163 GB5310/6579/9948/YB235-70

|

|

Length

|

5.8m 6m Fixed, 12m Fixed, 2-12m Random

|

|

Place of Origin

|

China

|

|

Outside Diameter

|

1/2'--24'

|

|

21.3mm-609.6mm

|

|

Technique

|

1/2'--6': hot piercing processing technique

|

|

6'--24' : hot extrusion processing technique

|

|

Usage /Application

|

Oil pipe line, Drill pipe, Hydraulic pipe, Gas pipe, Fluid pipe,

Boiler pipe,Conduit pipe, Scaffolding pipe pharmaceutical and ship building etc.

|

|

Tolerance

|

±1%

|

|

Processing Service

|

Bending, Welding, Decoiling, Cutting, Punching

|

|

Delivery Time

|

8-14 days

|

|

Material

|

ASTM / ASME A53 Gr.A, Gr.B, Gr.C A106 Gr.B, Gr.C A179 A192 A199 A210 A213 T5, T9, T11, T12, T22, T91 A333

DIN St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 St37.0, St44.0, St52.0, St52.3 RSt34-2, RSt37-2, RSt44-2, St52

BS 3059 360, 410, 440, 460, 490

GB 10#,20#,35#,45#,20cr,40cr,16Mn(Q345A,B,C,D),20G,15M0G, 15CrMo,30CrM0,42Crmo,27SiMn, 20CrMo Q235B

|

|

End

|

Bevel end(>2"), Plain (≤2"),with plastic cap, with screwed and socket

|

|

Surface

|

Black Painted, Galvanized, Natural, Anticorrosive 3PE coated,polyurethane foam Insulation

|

|

Packing

|

Standard Sea-worthy Packing

|

|

Delivery Term

|

CFR CIF FOB

|

Product Parameters

The seamless steel pipe is made by perforating the whole round steel, and the steel pipe without weld seam on the surface is called seamless steel pipe.

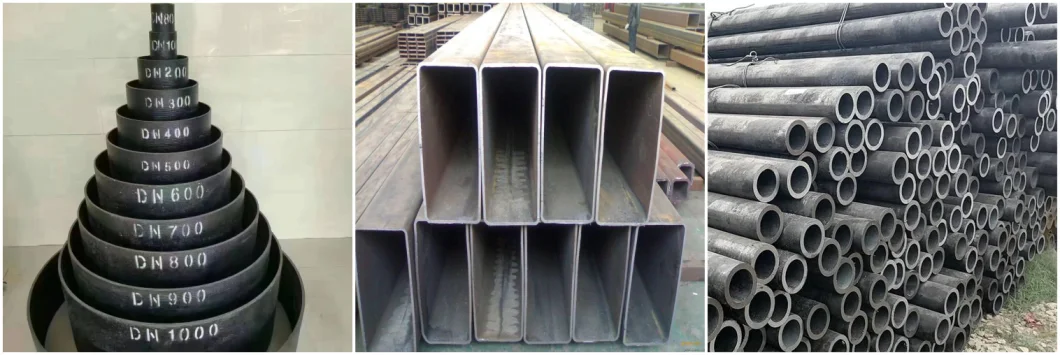

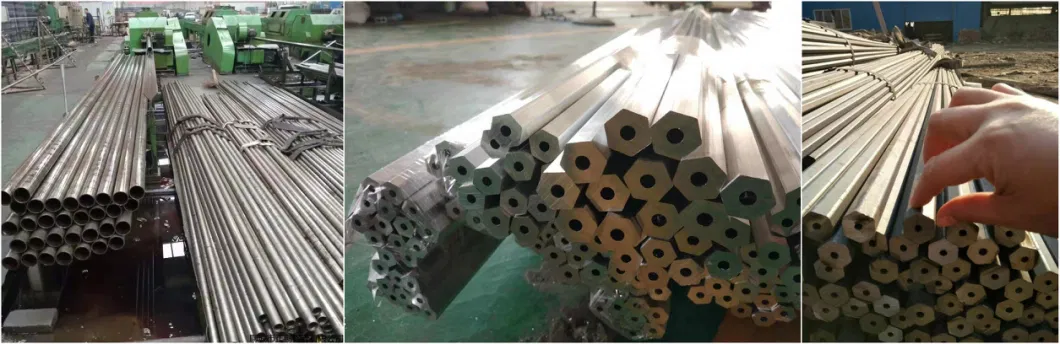

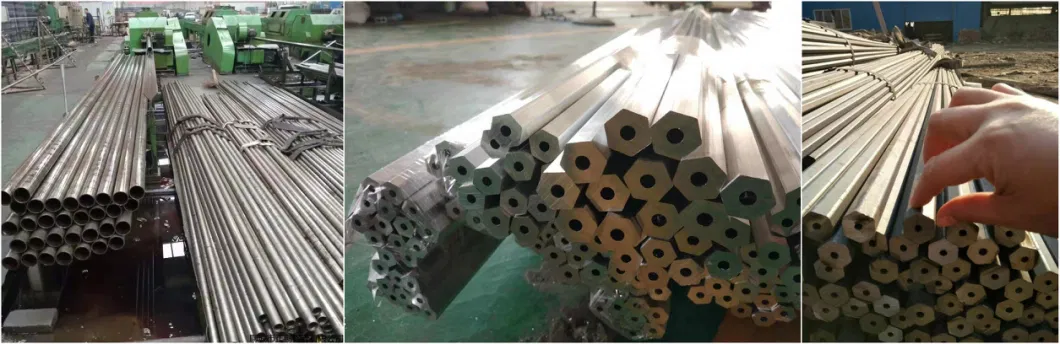

According to the production method, seamless steel pipes can be divided into hot-rolled seamless steel pipes, cold-rolled seamless steel pipes, cold-drawn seamless steel pipes, extruded seamless steel pipes, and pipe jacking. According to the cross-sectional shape, seamless steel tubes are divided into two types: round and special-shaped, and special-shaped tubes have various complex shapes such as square, oval, triangular, hexagonal, melon-shaped, star-shaped, and finned tubes.

The maximum diameter is up to 900mm and the minimum diameter is 4mm.

According to different uses, there are thick-walled seamless steel pipes and thin-walled seamless steel pipes.

Seamless steel pipes are mainly used as petroleum geological drilling pipes, cracking pipes for petrochemical industry, boiler pipes, bearing pipes, and high-precisi

Detailed Photos

Company Profile

is a cross-border steel supplier that integrates production and trade. We have professional production and sales departments, mainly producing carbon steel pipes, alloy steel pipes, hollow anchor rods. In addition, steel plates, galvanized plates, and steel wires are also our common trading products. We are not only a manufacturer but also a stock keeper We normally keep more than 5,000 tons of pipes in various sizes and standards. Our stock pipe size ranges from 20mm to 406mm in outside diameter and from 2mm to 70mm in wall thickness.We are a sales and export agent of local famous mills in China.

FAQ

Q1: Are you a factory or trading company?

A1: Tianjin Youfa Steel Co., Ltd. is a cross-border steel supplier that integrates production and trade.

Q2: Can I get samples before order?

A2: Yes, of course.

Q3:what is your delivery time?

A3:The time of delivery is usually around 15 days. We can send out in 3 days if it has stock.

Q4:What is your payment terms?

A4: Our usual payment term is 30% deposit, EXW, FOB, CFR, CIF.

Q5: What do your factory do regarding quality control?

A5:We have gained ISO, CE,API ,SGS,BV,authentication. From material to products, each product has to go through 4-5 processes.

Inspection, accompanied by corresponding quality inspection

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!