Product Description:

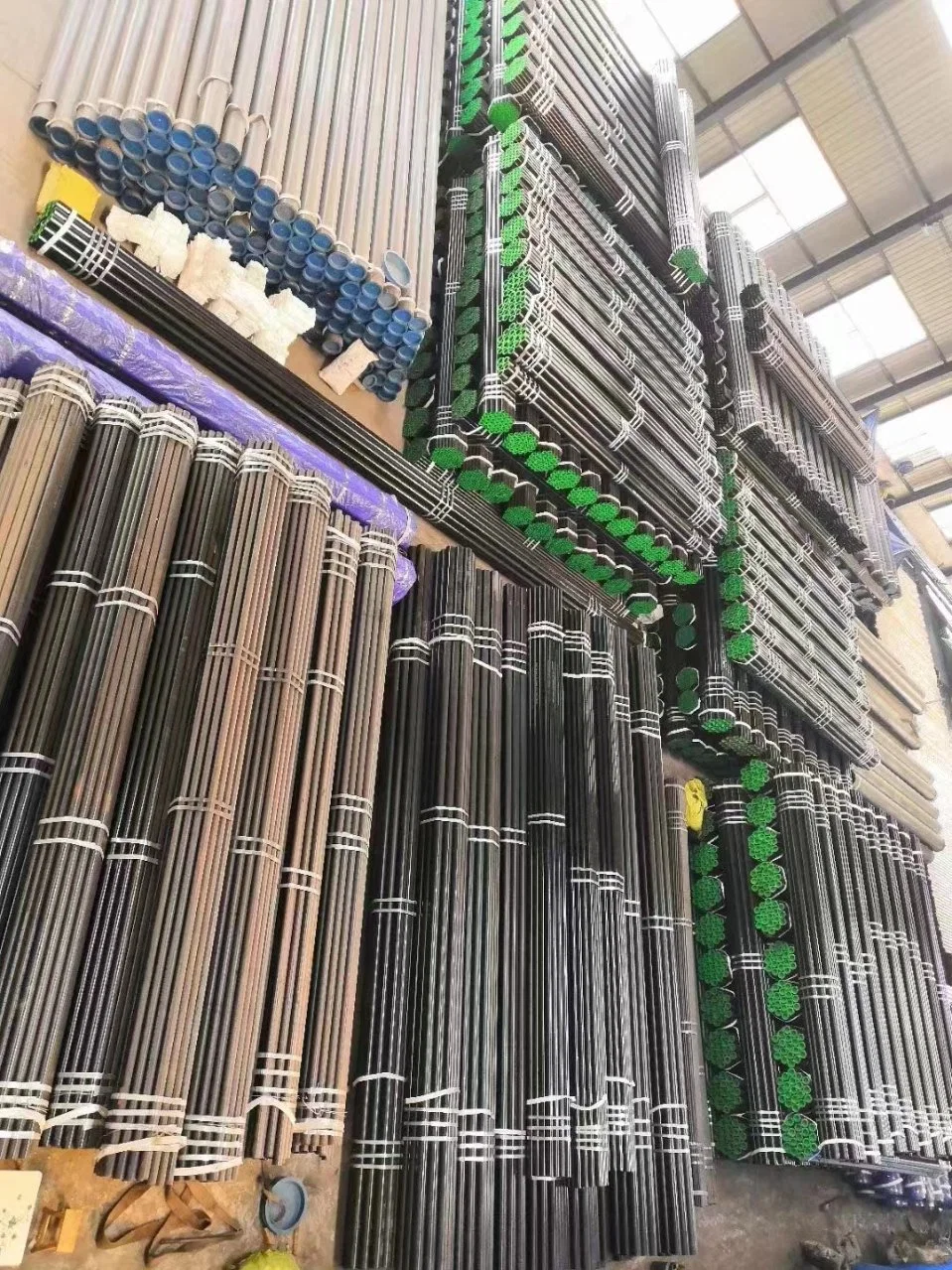

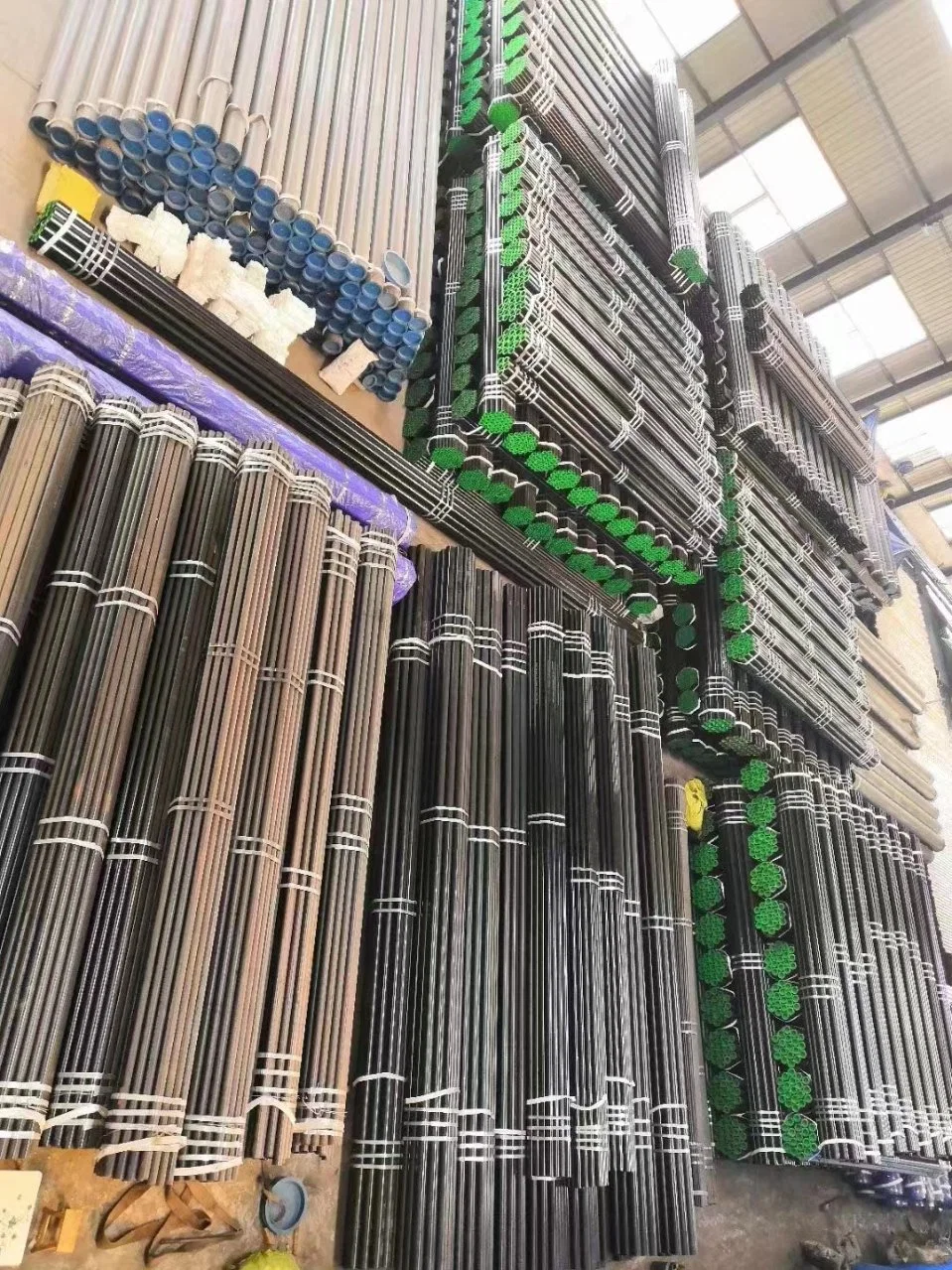

Product Overview: Carbon Steel Pipe

Carbon steel pipe is a type of steel pipe that is made of carbon and iron, with a varying amount of carbon content. It is a versatile and durable material that is commonly used in various industries, such as construction, oil and gas, and manufacturing. The following is a detailed overview of the product, highlighting its key attributes.

Tolerance: ±1%

Tolerance refers to the allowable deviation from the specified dimensions or properties of a product. In the case of carbon steel pipe, the tolerance is set at ±1%, meaning that the actual dimensions and properties of the pipe can deviate by up to 1% from the specified requirements. This ensures that the pipe meets the required standards and can perform its intended function effectively.

Processing Service: Welding, Punching, Cutting, Bending

Carbon steel pipe can undergo various processing services to meet the specific requirements of different applications. These services include welding, punching, cutting, and bending. Welding is the process of joining two or more pieces of metal together, while punching involves creating holes in the pipe. Cutting and bending, on the other hand, are used to shape the pipe according to the desired dimensions and angles.

Feature: Lasting Performance

One of the key features of carbon steel pipe is its lasting performance. Due to its high strength and durability, it can withstand harsh environmental conditions, high pressure, and extreme temperatures without compromising its structural integrity. This makes it a reliable and cost-effective choice for a wide range of applications.

Technology: Seamless Hot Rolled

Carbon steel pipe is manufactured using advanced technology and techniques. The most common method is seamless hot rolled, where the steel is heated and then rolled to form the desired shape and size. This results in a strong, seamless pipe with no welded joints, making it less prone to leaks and defects.

Third Party Inspection: SGS, BV, TUV, ABS, DNV, LR, GL, ASME

To ensure the quality and reliability of carbon steel pipe, third-party inspection is often conducted by reputable organizations such as SGS, BV, TUV, ABS, DNV, LR, GL, and ASME. These inspections involve rigorous testing and evaluation of the product to ensure that it meets the required standards and specifications.

In conclusion, carbon steel pipe is a versatile and durable product that offers lasting performance and can be processed to meet specific requirements. It is manufactured using advanced technology and undergoes third-party inspection to ensure its quality and reliability. With its various features and applications, carbon steel pipe is an essential component in many industries.

Basic Info.

Package

Package: Standard Sea Package or as Customer Requi

Production Capacity

500000tons/Year

Product Description

Seamless steel pipe is made of the whole round steel, and the steel pipe without weld on the surface is called seamless steel pipe. Seamless steel pipes are mainly used as drilling pipes for petroleum geology, cracking pipes for petrochemical industry, boiler pipes, bearing pipes and high-precision structural steel pipes for automobiles, tractors and aviation.

| Product Name |

Seamless Steel Pipe |

| Standard |

API 5L Seamless Carbon Steel Pipe for Gr B X42 X46 X52 X56 X60 X65 X70 Psl-1/Psl-2

API 5L,AP175-79, DIN2I5L , ASTM A106 Gr.B, ASTM A53 Gr.B,DIN17204

ASTM A179/A192/A213/A210 /370 WP91, WP11,WP22.

DIN17440, DIN2448,JISG3452-54.

|

| Material |

API5L Gr.A&B, X42, X46, X52, X56, X60, X65, X70, X80,

ASTM A53 Gr.A & B, ASTM A106 Gr.A&B, ASTM A135,

ASTM A252, ASTM A500, DIN1626, ISO559, ISO3183.1/2,

KS4602, GB/T911.1/2, SY/T5037, SY/T5040

STP410, STP42.

|

| Certificates |

API5L ISO 9001:2008 TUV SGS BV etc. |

| Outside Diameter |

1/2'--48', 21.3mm-61219mm or customized. |

| Thickness |

SCH5S, SCH10S, SCH20S,SCH20, SCH30,STD, SCH40, SCH60, SCH80, SCH100, SCH140, SCH160,XS, (1.65mm-80mm), or customized. |

| Length |

5.8m 6m Fixed, 12m Fixed, 2-12m Random. |

| Technic |

1/2'--6': hot piercing processing technic, 6'--48' : hot extrusion processing technic |

| Surface Treatment |

Black Painted, Galvanized, Natural, Anticorrosive 3PE coated,polyurethane foam Insulation. |

| End |

Bevel end(>2"), Plain (≤2"),with plastic cap, with screwed and socket. |

| Usage / Application |

Oil pipe line, Drill pipe, Hydraulic pipe, Gas pipe, Fluid pipe, Boiler pipe,Conduit pipe, Scaffolding pipe pharmaceutical and ship building etc. |

Package: Standard sea package or as customer required, fumigation free wooden frame + kraft paper packaging, with galvanized iron sheet fixed at four corners.

It is an enterprise integrating the producing, processing and saling of ductile cast iron pipe, steel pipe, steel plate, steel coil, steel bar, aluminum coil, aluminum pipe, aluminum bar, copper pipe, copper plate, copper bar and other metal materials.

After years of deep cultivation in the metal material export industry, our products are exported to Southeast Asia, the Middle East, South America, Africa, Russia and other regions and countries. And many customers have established a deep cooperative relationship.

At the same time, our factory has also trained an excellent foreign trade talent. It can help customers solve various problems encountered in the import process, provide customers with high-quality products, arrange convenient and cost-effective transportation of goods, and provide bills of lading, packing lists, invoices, certificates of origin and other documents to help customers clear customs and reduce import duties.

We believe that products with reliable quality and low price, fast and preferential transportation services and professional document support services will certainly impress you. If you need to import any metal materials, please contact us. Waiting for you.

We believe that products with reliable quality and low price, fast and preferential transportation services and professional document support services will certainly impress you. If you need to import any metal materials, please contact us. Waiting for you.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

We believe that products with reliable quality and low price, fast and preferential transportation services and professional document support services will certainly impress you. If you need to import any metal materials, please contact us. Waiting for you.

We believe that products with reliable quality and low price, fast and preferential transportation services and professional document support services will certainly impress you. If you need to import any metal materials, please contact us. Waiting for you.